Components keep their cool in 3D

A feasibility study has examined the use of over-moulding to create 3D electronic components with high thermal conductivity (writes Nick Flaherty).

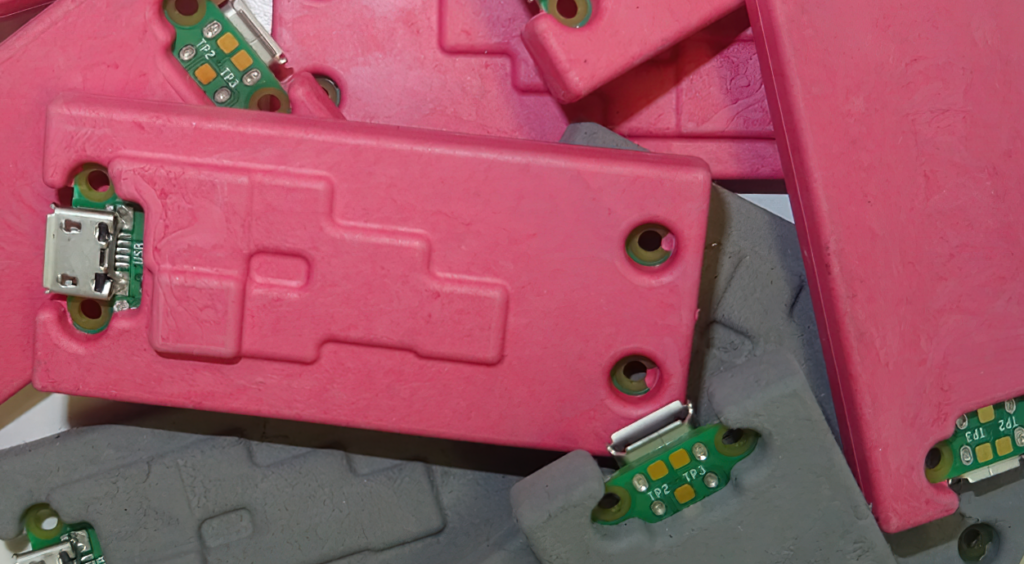

The project, at Sobaplast in Germany, uses the Keratherm MT 103 and MT 320 injection moulding materials from Kerafol on circuit board samples at temperatures that did not compromise the components on the board but still provided a high level of performance. This achieved electronic parts fully covered with thermally conductive but electrically isolating properties.

The thermal conductivity results from the filling of the polymer with ceramic fillers such as AL2O3. This is a new approach that allows the circuit board and cooling plate to be connected in 3D. That means they can ensure higher levels of thermal management and simultaneous protection against environmental influences.

The melt flow index (MFI) of the materials is a key consideration for filling the mould without creating air bubbles, also called inclusions. MT320 has an MFI of 10-20 g/10 minutes at 170 C, while MT103 has an MFI of 4-10 g/10 minutes at the same temperature. Inclusions in the moulding would compromise the thermal performance, creating hotspots.

Visible streaks on the surface of the samples are not critical, and are typical for highly filled plastics such as parts with a metallic pigment for household appliances and toys, said Kerafol.

The low processing temperatures of the materials, of 150 to 180 C, are key to avoiding stress on circuit board components. The study examined the effective use of the materials at 150 ± 20 C up to 180 ±20 C.

ONLINE PARTNERS