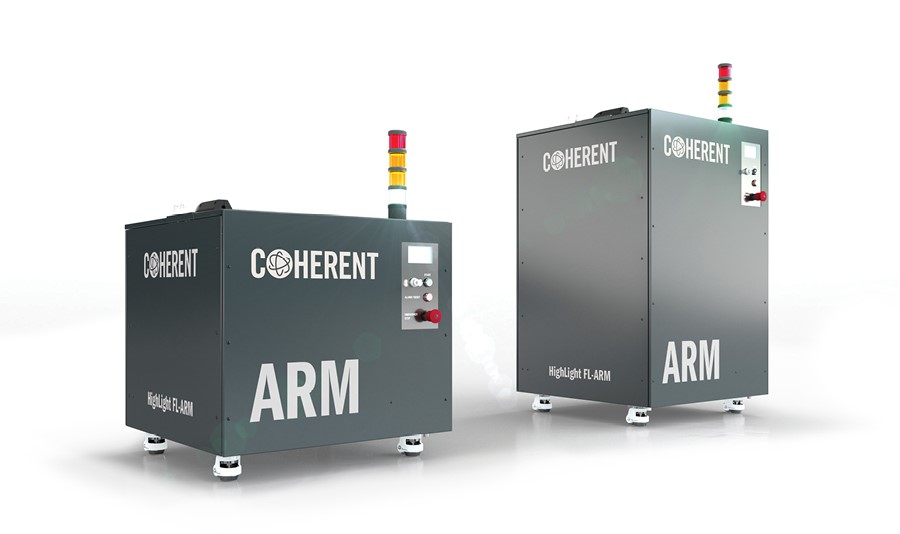

Coherent introduces new fibre lasers for EV battery manufacture

(Courtesy of Coherent)

Coherent has introduced a range of adjustable ring mode (ARM) lasers, part of the HighLight FL‑ARM series, which are designed to enhance the control of the welding process over large working areas. Target applications are those that are common in battery manufacturing for EVs.

The new lasers feature longer collimated beam lengths and smaller spot sizes that enable deep welds with greater uniformity over large working areas. The beams’ characteristics make them suitable for use on thick busbars and motor stator hairpins.

Coherent also recently introduced improvements to two processing heads, the HighMotion 2D and the PH20 SmartWeld+, both of which work with HighLight FL-ARM lasers.

The HighMotion 2D is suited to applications where the beam has to be quickly moved about a stationary workpiece to complete multiple welding tasks. The PH20 SmartWeld+ is for longer weld seams or weld layouts of individual battery cells. Both use a detachable fibre delivery system with a 100 µm inner diameter and a 290 µm outer diameter to connect to the ARM laser. The HighLight FL-ARM produces two individually controllable coaxial beams from a single fibre, with up to 2.5 kW in the centre beam and 7.5 kW in the outer ring. These enable power levels in both the central spot and the surrounding ring to be adjusted independently

ONLINE PARTNERS