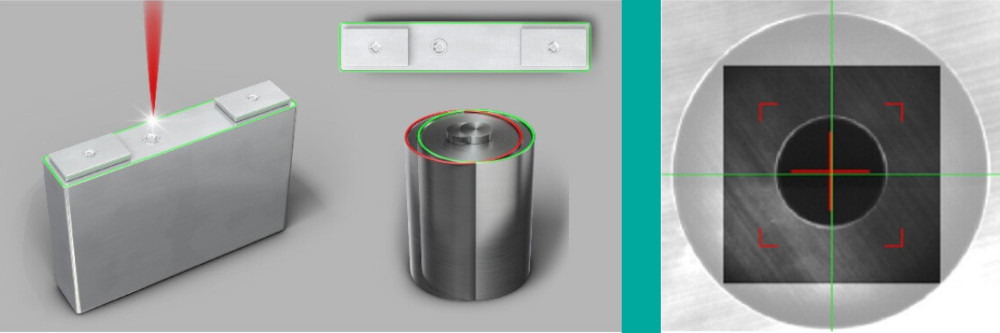

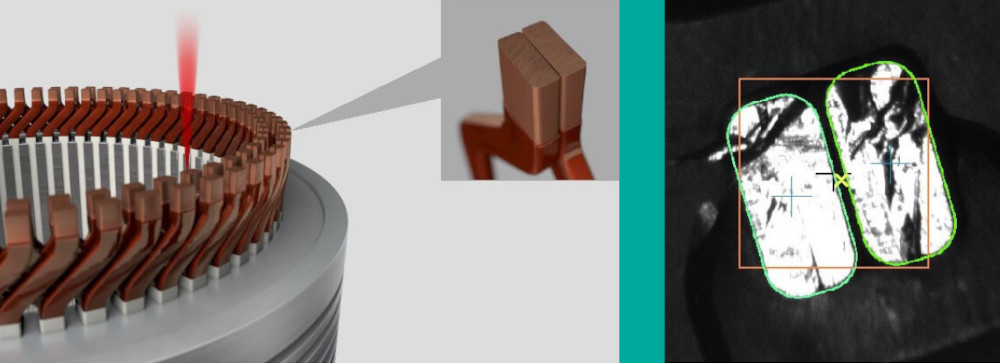

Coherent announces integration of laser welding head vision system for EV battery and motor manufacturing

(Images courtesy of Coherent)

Coherent has unveiled HIGHvision, a machine vision system for laser-welding heads that it says greatly improves the efficiency of manufacturing EV batteries and motors.

HIGHvision is a turnkey system consisting of machine vision hardware and software that enables laser welding heads to align to software-defined features on the workpiece in milliseconds and with high accuracy. Coherent says it greatly accelerates welding throughput.

The laser-welding heads have been designed around an embedded vision system architecture. They can be seamlessly integrated with Coherent’s HighLight FL-ARM lasers, providing an all-in-one solution to optimise welding process parameters.

HIGHvision includes a library of processing applications, including welding battery busbar, tab and can-cap assemblies, as well as electric motor stator hairpins. It is available as an option for the HIGHmotion 2D and RLSK remote laser-welding heads. The library of applications will continue to be developed, and will include AI-assisted algorithms.

ONLINE PARTNERS