Cheaper, more efficient MOSFETs

iDEAL Semiconductor has developed a technology that can improve the efficiency and cut the cost of power MOSFETs for e-mobility applications (writes Nick Flaherty).

The SuperQ process technology can also be applied to SiC MOSFETs and GaN transistors in the future, said Mark Granahan, CEO and founder of iDeal Semiconductor.

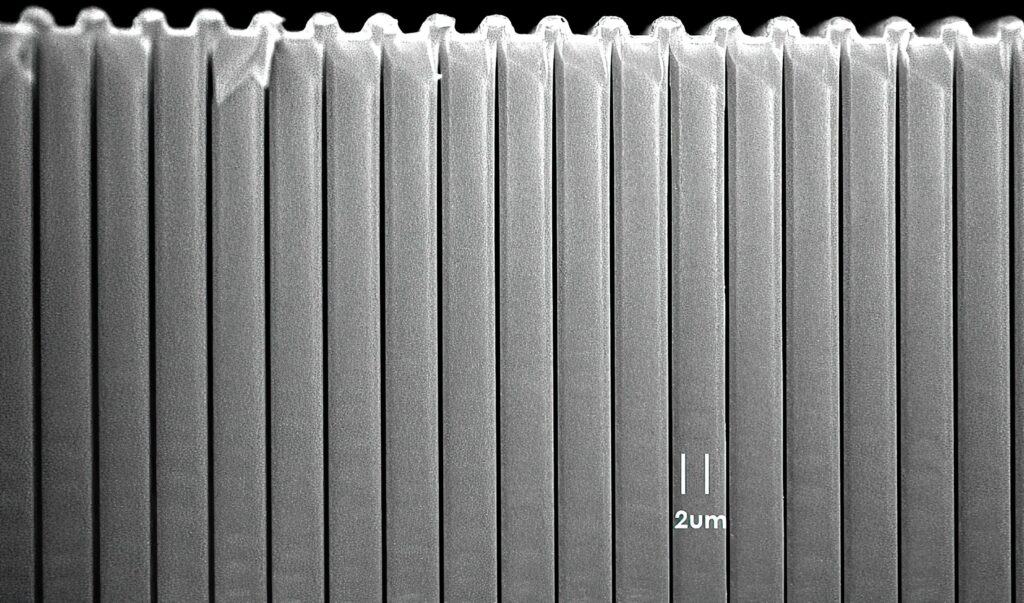

SuperQ uses a combination of new dielectric materials, etching and atomic layer deposition (ALD) to improve the performance of power devices for motor control. The process enables a much lower specific on-resistance (RSP) for a much lower on-resistance in the device, which in turn improves the switching performance as the die is smaller.

iDEAL is aiming to produce transistors and diodes up to 850 V, as the same process can be used for devices from 60 to 850 V rather than having to use multiple technologies to cover the voltage range.

“Our technology gives a voltage blocking of 19-20 V/µm, a 30% improvement over other processes, so our epitaxy is much thinner,” said Granahan. “The conduction area is also greatly expanded so we have more area, and that improves the RSP. The larger conduction area and higher doping concentration deliver an effective high-voltage blocking technique.”

Using chip-making tools from the CMOS world also makes the process simpler and cheaper. The company is using the process to build its own 650-800 V MOSFETs with foundry partners including Polar Semiconductor, although the devices are not automotive-qualified. However, they can be used for other e-mobility platforms such as e-bikes.

“Rather than epitaxial implant with over 18 masks and long process times, or trench and refill with 14 masks, our etch and ALD deposition has around 10 masks so our capital cost is low and the process is shorter,” said Granahan.

“Our MOSFET structure is very simple. The mask count is about 10-11, and that plays to the reliability of the device. We have done a lot of work on reliability testing to prove out the technology, and it shows that the breakdown voltage and leakage current are stable over time.”

SuperQ is also being used to boost the switching frequency of designs. “The structure of the device is optimised for fast switching,” said Granahan. “We can easily break 150 kHz, which is the upper range of power designs.”

As for SuperQ’s application to GaN and SiC as well as silicon, Granahan said, “Our perspective is that SiC and GaN are great power materials but they have a lot of fundamental issues in manufacturability that the industry has yet to work through.

“The defect levels still impair the cost level that the market needs for it to expand. There are applications such as EV drivetrains that seem to be a nice spot for them, as cost is not so much of an issue.”

“Vertical GaN devices for moving the grid to an electrified world is interesting, and SuperQ is applicable to that structure to improve the resistivity,” he said. “That’s why we believe it can be applied to silicon, SiC and vertical GaN devices. In the longer term we believe that SuperQ will be applicable to wide bandgap technology so we are agnostic regarding the transistor materials, and once the SiC world works through the fundamental defect levels we can apply the technology there.”

ONLINE PARTNERS