CATL launches cell-to-pack battery and claims highest integration level so far

(Images courtesy of CATL)

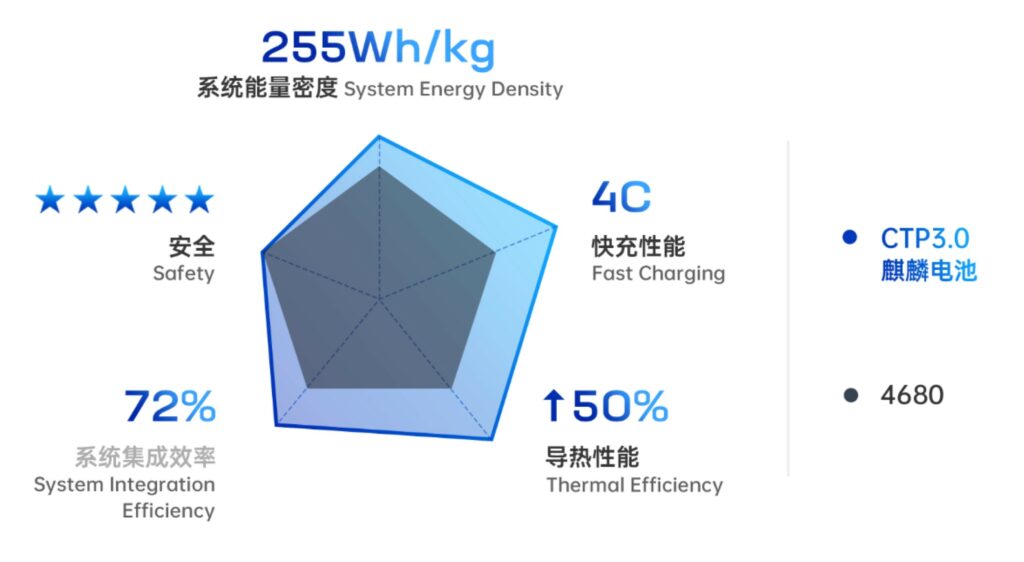

CATL has announced Qilin, the third generation of its cell-to-pack technology dubbed CTP 3.0. The company says it gives a volume utilisation efficiency of 72% and an energy density of up to 255 Wh/kg, to deliver a range of more than 1000 km.

In the Qilin, which is named after a legendary creature in Chinese mythology, the internal cross-beam, liquid-cooling plate and thermal pad have been integrated into a multi-functional elastic interlayer. It also features built-in micron bridges inside the interlayer, which flexibly accommodate changes inside the cell, improving the battery’s reliability throughout its full life cycle.

The integrated energy unit, which is composed of the cell and the elastic interlayer, provides a more stable load-bearing structure perpendicular to the driving direction, enhancing the shock and vibration resistance of the battery pack.

A bottom-sharing design allows a smart arrangement of components as well as structural protection, a high-voltage connection and a protective vent for thermal runaway, which serve to increase the battery’s capacity by a further 6%. The battery also satisfies the criteria of safety tests required by national standards.

By placing liquid-cooling functional parts between adjacent cells, the large-surface cell-cooling technology increases the heat transfer area by four times, cuts thermal control time in half, and supports a hot start in 5 minutes and fast charging in 10 minutes. It enables the cell to cool down rapidly in extreme circumstances, preventing abnormal thermal conduction among cells.

It also provides thermal stability and thermal safety for all chemical systems, making it compatible with materials with higher energy densities.

The Qilin can increase the energy density to 255 Wh/kg for ternary battery systems, and to 160 Wh/kg for LFP systems. With the same chemical system and pack size, it can deliver 13% more power than a 4680 battery.

The batteries are expected to come on the market in 2023.

ONLINE PARTNERS