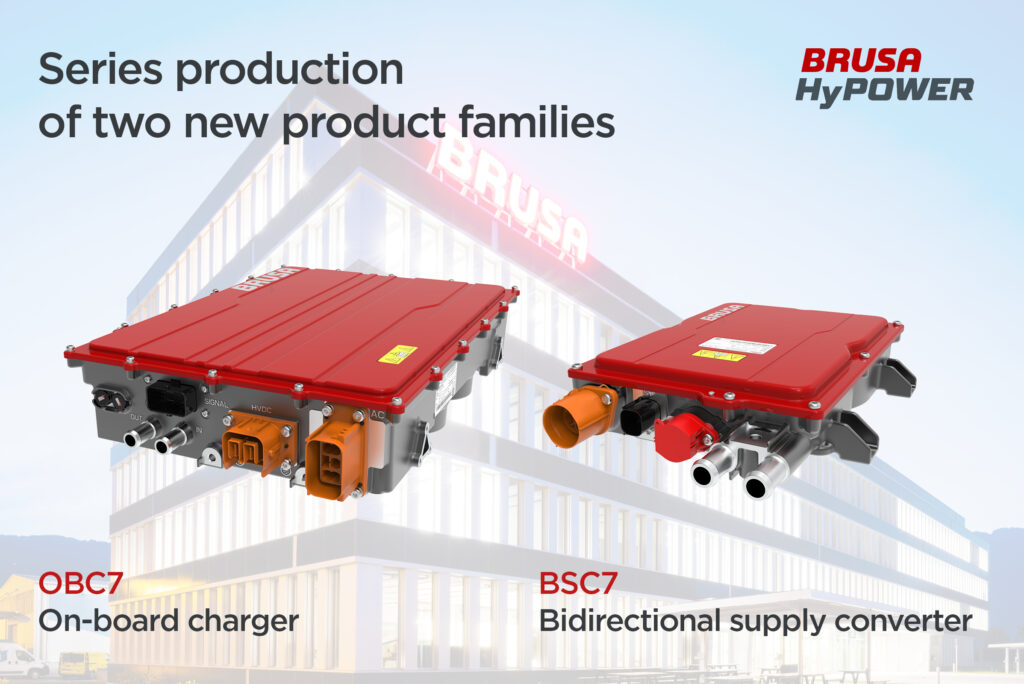

BRUSA HyPower ramps up series production of OBC7 and BSC7

(Image courtesy of BRUSA HyPower)

BRUSA HyPower has moved its latest power electronics from the development lab into series production, with the Swiss manufacturer now shipping its OBC7 and BSC7 systems to commercial vehicle and off-highway equipment builders. The move represents a significant step up from prototype supply to volume manufacturing for the company’s automotive-certified power electronics.

The OBC7 onboard charger tackles one of the persistent challenges in commercial EV deployment: flexible charging power that can adapt to varying infrastructure capabilities. Rather than locking operators into fixed charging rates, the system allows multiple units to be connected in parallel, scaling power delivery from the base 22 kW up to whatever the application demands.

This scalability proves particularly valuable in commercial applications where charging infrastructure often lags behind vehicle capabilities. A logistics operator might install basic 22 kW charging initially, then add parallel units as their fleet grows or faster charging becomes economically viable.

The charger works across both 400 V and 800 V battery architectures, delivering 19.2 kW on single phase connections and the full 22 kW rating through three phase supplies. BRUSA HyPower has built the system around cost-optimized silicon carbide technology with galvanic isolation, integrating DC charging management directly into the unit rather than requiring external controllers.

While onboard chargers handle energy flowing into the vehicle, the BSC7 bidirectional supply converter addresses the growing interest in using commercial vehicles as mobile energy storage. Fleet operators are beginning to see their vehicles not just as transport assets but as grid resources that can generate revenue through demand response and peak shaving services.

The BSC7 enables power flow in both directions between high voltage battery packs and low voltage vehicle systems. At just 56 x 196 x 272 mm and under 4 kg, the converter fits into tight packaging constraints while maintaining galvanic isolation between high and low voltage sides. This isolation proves critical for safety certification in automotive applications.

Commercial vehicle operators face different challenges than passenger car owners. Their vehicles must withstand extreme operating conditions, from construction sites to loading docks, while maintaining reliability over extended service intervals. BRUSA HyPower has designed both systems to meet the environmental and durability requirements typical of commercial vehicle operation, addressing temperature extremes and vibration levels that would challenge passenger car components.

The transition from prototype to series production often reveals the gap between laboratory performance and real-world manufacturing. BRUSA HyPower’s approach emphasizes scalable production processes that can accommodate varying OEM requirements while maintaining consistent performance across different vehicle platforms.

For manufacturers developing electrified commercial vehicles, the availability of proven power electronics from established suppliers reduces development risk and accelerates time to market. Rather than developing proprietary charging and power management systems, OEMs can integrate BRUSA HyPower’s certified components and focus resources on vehicle-specific engineering challenges.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS