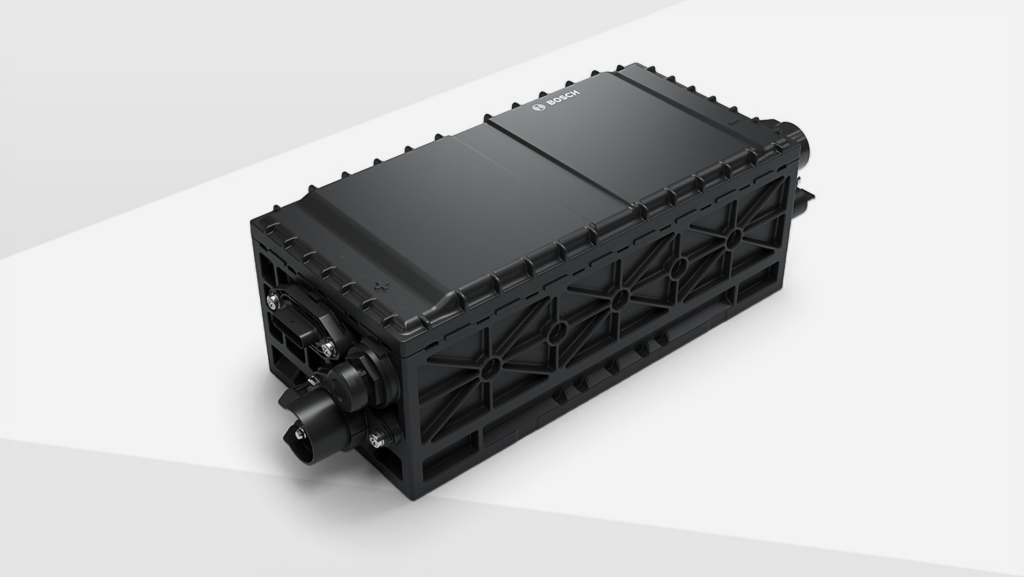

Bosch chooses DELO adhesives for mild-hybrid system

(Image courtesy of Bosch)

With 48 V batteries able to reduce vehicle carbon emissions by up to 15%, Bosch offers manufacturers a powerful solution with its mild-hybrid battery. An adhesive from DELO plays a substantial role in its integration.

Mild-hybrid systems play an important role in the drive towards zero emissions and 48 V batteries serve as the core element. By supplementing power to the internal combustion engine, they help to reduce fuel consumption and CO2 emissions. Bosch expects 20% of all cars and light commercial vehicles sold to be powered by mild-hybrid powertrains by 2025.

Bosch’s 48 V battery offers good thermal conductivity of 1.0 W/(mK). This means battery cells can not only be bonded into the housing but the heat generated during operation can be dissipated efficiently. As a result, the adhesive combines structural bonding and thermal management system mounting in one step, instead of having to manually fix battery cells and then use gap fillers for heat dissipation.

The product is flame-retardant in accordance with industry standard UL 94 V-0, designed for the entire temperature range of the battery, and it offers high strength on cells and typical housing materials. Its tensile shear strength on aluminum is 18 N/mm². It has also been optimised for manufacturing processes. Easy to detect through cameras, it allows Bosch to carry out precise application control, giving high quality assurance.

The 48 V systems from Bosch are so compact that they give vehicle manufacturers maximum flexibility during installation. The battery is only 140 mm high, so it can be placed in the trunk or under the passenger seat.

Bosch has worked with partners to develop robust lithium-ion cells, which even work at temperatures of up to 75 C.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS