Bob Prohaska of Pratt Miller explains drive cycle analysis for next-gen vehicles

(Image: Pratt Miller)

Realising potential

Bob Prohaska, director of mobility projects at Pratt Miller, speaks to Will Gray about applying drive cycle analysis, engineering partnerships and systems thinking to next-generation vehicle development

Understanding exactly what the vehicle you want to electrify will do on its daily schedule might sound like a fundamental starting point in the development process, but many fail to understand just how important it can be. That is one of the biggest learnings Bob Prohaska has taken away from his career in the industry and, as a developer of pioneering prototypes, it is one he tries to integrate into every starter conversation he has with a prospective client.

Prohaska’s route to becoming director of mobility projects at Pratt Miller began right at the grass roots, “wrenching on equipment” in his dad’s construction and earth moving company workshop for years. He gained his Class A commercial driver’s license as soon as he turned 18 and quickly learned to speak “heavy truck.” His BSc in mechanical engineering from Michigan Technological University (USA) then created a blend of educated technical know-how and on-the-ground, hands-on experience that has served him well throughout his career.

Graduating in the late 2000s during the global financial crisis, his plan to turn his university placement into a job at Toyota collapsed owing to a hiring freeze. Instead, he joined BAE Systems’ Weapons and Turrets group, where he began to gain valuable experience in fundamental fabrication and design tolerancing. Although not directly involved in the EV space, he did have brief oversight of a ‘Future Combat Systems’ (FCS) project that was in development.

“A good portion of our organisation was focused on that project,” he recalls. “There was a lot of talk about electrification and advanced technologies in the hallways, and some fundamental research was being carried out on motors, inverters, controllers and different power units. Unfortunately, that got cancelled shortly after I started, but some of that FCS work has been repurposed or was used as a stepping stone now that we are further down the road.”

His defence experience took him to Navistar Defense, where he worked on tactical wheeled vehicles, specifically updating the MaxxPro MRAP vehicle that was used as a workhorse in both Iraq and Afghanistan. It combined a commercial truck chassis with an armoured capsule, and one upgrade project that his team worked on involved replacing the standard transmission with a Transmission Integral Generator, which added an integrated motor to enable power offboarding for a variety of tactical operations. Although still nascent technology, it was a function that would be of increasing appeal in the sector.

When family choices took him to Colorado, an internal transfer saw him join the commercial vehicle operations at Navistar, running vehicles across the country to accumulate miles on medium- and heavy-duty vehicles for On-Board Diagnostics (OBD) system compliance, warranty mitigation and engineering validation. However, it was his next career move – to the National Renewable Energy Laboratory (NREL) as an advanced vehicle fleet test and evaluation engineer – that truly began his connection with the world of EVs and other alternative energy options.

One of his first meetings saw him sitting amongst a group of world-class and well-cited PhD experts and he recalls: “I remember being surrounded by renowned researchers from around the world thinking to myself: ‘Yeah, I’m just the truck guy from down the street.’ I felt like I had just snuck in on this completely different world – but in fact my hands-on experience served me really well when it came time to executing the projects. The team appreciated my ability to ‘speak the language’ of the fleet managers and drivers, while also being able to work in a highly academic, heavily PhD-oriented research group.”

(Image: NREL)

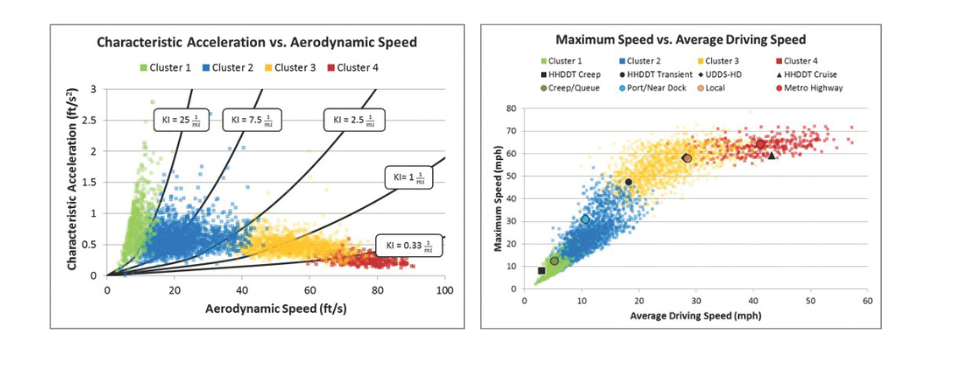

Hands-on engineering was replaced by research and writing papers, and his first work involved evaluating duty cycles for a fleet of Frito-Lay’s Class 4 EVs operating in Seattle and Phoenix – a future-focused project that would turn out to be a key part of his career. “We were using telematics data to characterise the benefits of an EV compared to a diesel,” he recalls. “The one big metric we focused on was Kinetic Intensity [KI] – a clever metric comparing the ratio of energy used to accelerate the vehicle versus energy used to overcome aerodynamic drag.

“At the time, the NREL’s mission was to help the Department of Energy understand how emerging vehicle technologies were being deployed, the barriers to adoption and where targeted r&d funding could accelerate commercialisation. The KI metric gave us a single number that would tell us whether a specific duty cycle might suit a particular type of technology – such as EV, hybridisation, alternative fuels, hydrogen, etc. It did a really nice job of simplifying things and allowing us to compare collected data against standard simulated cycles like NYC Composite or CARB HHDDT.”

Prohaska later went on to apply this work to the duty cycles of port drayage vehicles – short-distance transportation of containerised goods from a port to a nearby warehouse – with the aim of better understanding the operational requirements and their potential for adoption of advanced technologies. That project involved collecting more than 36,000 miles worth of data from 30 Class 8 trucks at the Ports of Long Beach and Los Angeles, and the result was a paper that has gone on to educate the industry.

“That is one of the papers I’m most proud of because it was written to be approachable,” Prohaska states. “Through mathematical analysis and k-medoids clustering, we found different operating modes and created different drive cycles for these modes, using NREL’s DRIVE tool to stitch all these micro-trips together to create a synthetic duty cycle representative of that operation. I got to present that at the Society of Automotive Engineers Commercial Vehicle Engineering Congress and it was pretty well received.

“We also did a project with Miami-Dade County, analysing the use of hydraulic series hybrid refuse trucks. They did a great job at recouping energy because they make 1200 stops a day with a harsh drive cycle [high KI], but they struggled when they were running at high speed. They had a three-speed gearbox and the truck was just too heavy because it wasn’t optimised for the long high-speed portions of the routes back to the landfill. So, again, it’s all about understanding your duty cycle and what you’re trying to optimise for.”

The duty cycle analysis work resulted in the development of a web-based open-forum drive cycle analysis tool – NREL DriveCAT – that continues to enable developers to download drive cycle data, see different time series and determine where a specific cycle falls on the KI versus average driving speed graph. “The biggest takeaway for me from all that work was understanding the true importance of the drive cycle, the duty cycle and the different use cases of vehicles in the EV space,” continues Prohaska.

“It influences everything from battery sizing to power electronics, traction motors and inverters. It helps you know what your acceleration rate needs to be and how much power and torque you need. Knowing when you have sustained high-speed power and low amounts of regen helps you determine the appropriate motor sizing for sustained top speed, and on the regen side, ensuring you recapture the energy at the same rate at which it’s available helps to avoid creating lost opportunities for energy efficiency.

“There’re so many metrics that go into truly characterising operations and that becomes really important as you get into these vocational spaces because you’re no longer making emotional decisions; it’s all based on ROI [return on investment] and total cost of ownership. To this day, when I talk with startups or even mature OEMs, I always emphasise how important it is to accurately define the drive cycle so you can ensure that the advanced technology will work, size the system and components properly and understand all the downstream impacts.”

During his time at NREL, Prohaska also worked on grid-side charging implications for Frito-Lay’s EVs, investigating the benefits of onsite renewables by evaluating offset peak demand charging, solar deployment and load balancing approaches. He also carried out an electric shuttle project for Zion National Park, which combined both areas of expertise, looking at duty cycles and different charging approaches. This was around 2016, when there was not as much sophistication around charging as there is today, and he was able to use pioneering economic modelling to evaluate different approaches.

After almost three years with NREL, Prohaska returned to Detroit and secured a job back in defence with Milton Manufacturing, a former key supplier from his time at Navistar. It was an opportune move that he puts down to an underlying theme in his career: the importance of strong relationships. “I always tell young engineers that the people you meet, you’re going to meet again, and your reputation will precede you,” he says. “That’s exactly what happened when I moved back and was asked to join Milton’s special project group.”

(Image: Navistar Defense)

A sheet metal fabrication shop at its core, Milton had strong skillsets in prototype fabrication and assembly and did a lot of work on different demonstrators. Most did not relate to e-mobility, but he did work on one electrification project – a rather unusual paddle wheel pontoon boat. “It was pretty simple architecture,” he recalls. “It was a 48 V system with an electric motor driving a small gearbox. It was eight years ago and it’s still cruising around on the lake on the same set of batteries.”

Arguably, Prohaska’s biggest career move came a little over a year later, when he joined his current employer, Pratt Miller. Joining as a project lead, his work included an electric shuttle bus; a series-hybrid, autonomous robotic platform for the US Marine Corps Warfighting Lab; and a high-performance electric utility task vehicle (UTV) side project for heavy-duty battery and hydrogen fuel cell powered truck manufacturer Nikola, to name but a few. He has since risen through the ranks of chief engineer, senior chief engineer and director – and his most enjoyable work has come from interfacing with different customers and exploring new markets.

“We take projects from concept to reality,” he says. “Anything we take on needs to be interesting, have high levels of technical challenges, aggressive timelines and potentially be something that hasn’t been done before – that’s almost one of the project qualifiers here. It’s also important to be conscious that not every problem needs the same level of solution, so we try to be scalable in our approach. For example, if it’s trying to get to an investor day, we can do rapid prototype ‘monster garage’ builds; if it’s helping with a production validation, there are no opportunities for shortcuts.”

The business is split into thirds – motorsport, defence and mobility – and given his defence background, it is no surprise that Prohaska initially worked in that area. His first project was to develop an EMAV (Expeditionary Modular Autonomous Vehicle) platform for the Marine Corps Warfighting Laboratory – and he says the fully autonomous and tele-operable tracked robot, which was designed to fit inside a V-22 Osprey cargo aircraft, is still one of the “most technically dense platforms” he has ever worked on.

However, as with many projects, it had a bumpier ride with its supply chain than it ever did with obstacles in the field and he recalls: “Supply chain resilience is an underlying theme with a lot of prototype developments projects. On that project, the companies that developed the gen set and the battery both went out of business, so we had to design them in-house, and time and time again we have seen projects get torpedoed because a key component of the system becomes unavailable overnight.”

However, on the flip side, there are also challenges for startup developers who try to avoid such issues by building in-house and he adds: “Focus is a key attribute. We’re just as guilty as anyone of getting distracted by the new cool thing, but we really try to drive home the importance of keeping focused on key deliverables and milestones. If you try to solve all the permutations of the five-year road map on day one, you dilute the team, dilute your funding and then you can’t get to that next phase.”

The Nikola UTV project was another example of a fun and pioneering vehicle being halted by business realities. Prohaska fondly recalls the packaging challenge involved to create the incredibly capable 590 hp off-road machine, only for the development to be shelved to place greater focus on the core truck product. As the challenges of electrification evolved, Prohaska moved onto a Class 7 and 8 truck project with Hino Motors Manufacturing, developing 14 different prototypes based on their conventional diesel rolling chassis, before another promotion saw him take a wider perspective on business development.

In the last seven years, Prohaska has seen a dramatic change in markets for electrification. Initially, the core focus was in the automotive space, but as OEMs became more competent in that area, they developed the expertise to deliver in-house. The medium- and heavy-duty truck space was the next to require specialist attention, but with that now ready to move to the OEM level, Prohaska’s task is to explore the potential for innovation applying the same disciplined engineering mindset that defined early electrification to new frontiers in the construction, agriculture, marine and mining sectors.

“When a sector enters electrification, there are a lot of retrofit projects, people throwing parts at vehicles, not really looking at duty cycles and optimisation, so we help to accelerate that initial development by giving them a better systems-engineering approach,” he explains. “The OEMs react slower, but when they do react, they do a good job and they don’t need companies like us to fill in all the gaps anymore. A lot of initial electrification was incentivised by rebates or incentives, but now we’re seeing a lot of ROI-driven investment; applications that pay for themselves and I think that’s where we’re going to see things grow longer term.

“One of the big changes has been in the integration of components. When electrification was more nascent, everything was just a pile of parts thrown together and it looked like a senior design project; it didn’t look like a cohesive, well-optimised integrated system. There’s a lot of benefit in a cleverly designed, elegant system and we’re seeing more three- or four-in-one devices now; equally, suppliers are no longer on their first or second gen of a system, so they have figured out how to pull costs down and the supply chain has matured.

“As a company, we do a good job of staying on top of things as they’re evolving because we’re not locked into a certain piece of hardware and we’re supplier agnostic. Certainly, for batteries, looking across chemistries, cell types, modules, cooling methods, plate chillers, ribbons or fully flooded, it’s an evolving technology and we’re constantly evaluating what’s going to be more beneficial. There’s a lot of unofficial standardisation through best practice now, and that goes a long way to helping development as well.

Ultimately, though, it all comes back to understanding drive cycles and how vehicles are truly used. “Instead of a solution looking for a problem, if you can start with the problem and try to solve it from that perspective, you’re far more likely to succeed, especially in ROI-based applications,” he concludes. “In fact, some of the more fun opportunities I’ve had with clients in recent years were when I referenced them back to the NREL research on drive cycles. Sometimes, I wouldn’t tell them who wrote the paper and just let them make the connection!”

(Image: MOVE America)

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS