DELO and DATRON automated sealing boosts fuel cell manufacturing scalability and reliability

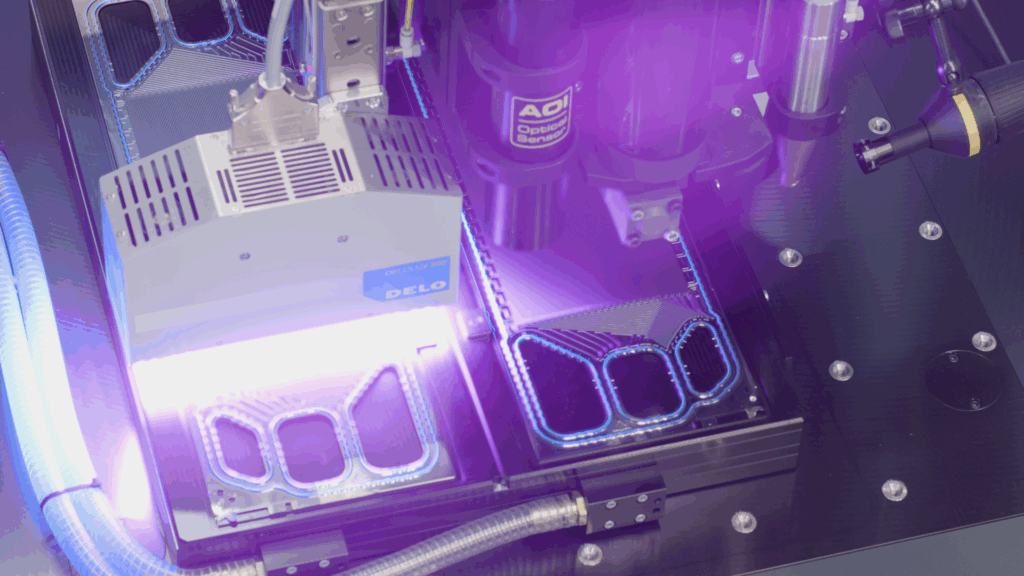

(Image courtesy of DELO)

The transition from prototype to volume manufacture in fuel cell production hinges on details that become critical at scale. One key factor is the sealing of individual fuel cells within a stack, where any breach in tightness risks long-term system reliability. DELO and DATRON offer a solution combining fast-curing adhesive technology with precision dispensing automation to industrialise fuel cell sealing without quality trade-offs.

At the core of the system is DELO PHOTOBOND SL, a liquid gasket material designed specifically for fuel cell use. Unlike conventional time-consuming and energy-intensive sealing methods, this material cures by light within seconds. It delivers high chemical resistance to sulfuric acid and deionized water, common in fuel cells, ensuring long service life.

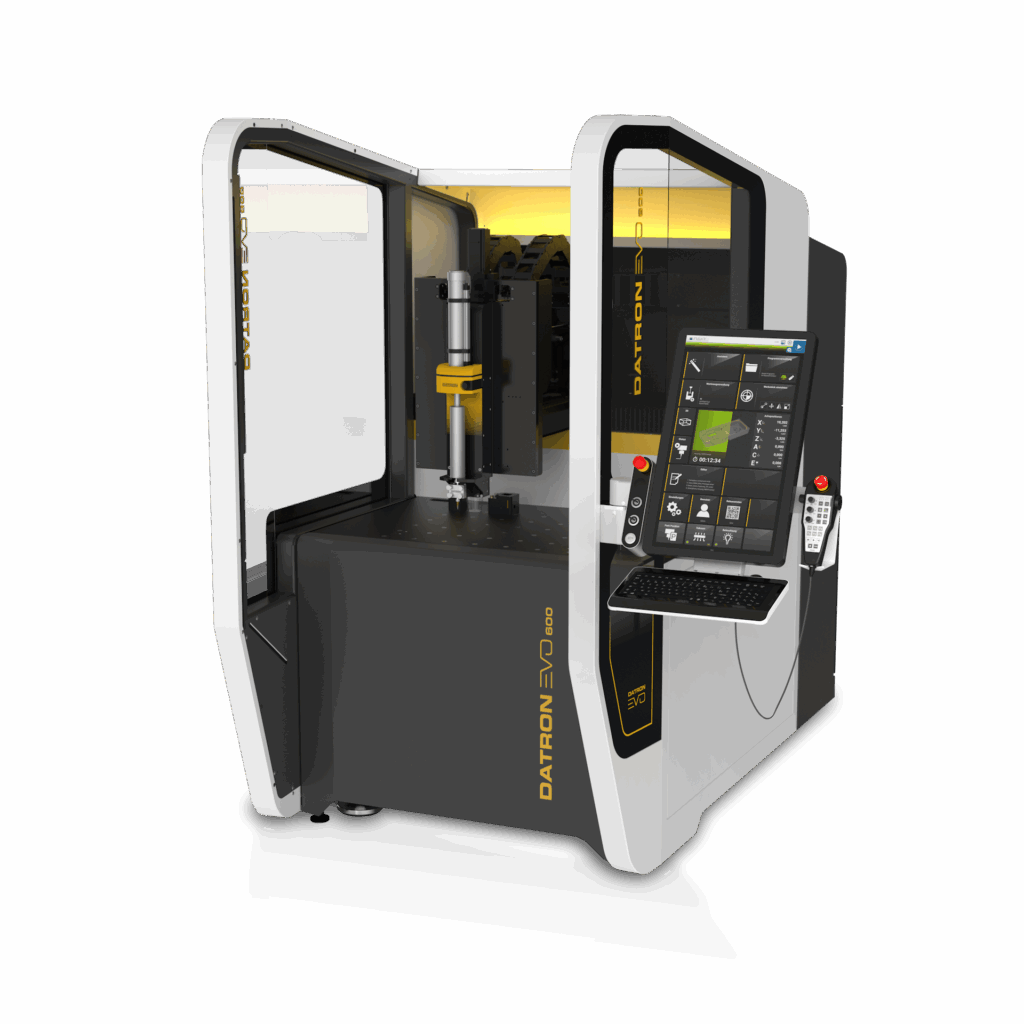

The DATRON evo 600 volumetric dispensing system applies the sealant at speeds up to 50 meters per minute while maintaining a constant bead cross-section – even at start and stop points. This consistency enables manufacturing of hundreds of fuel cells with uniform gasket geometry, essential to prevent leaks or stress when cells are stacked.

“Sealing the individual fuel cells is often an underestimated but decisive step in the entire stack manufacturing process,” says Julian Hopf, Product Manager for Energy Storage and Conversion at DELO. “Only if absolute tightness is achieved can the system operate reliably over the long term.”

(Image courtesy of DATRON)

The liquid gasket allows design flexibility, accommodating complex geometries without retooling, adaptable to evolving cell designs and stack configurations across automotive to stationary applications. Inline quality control uses a confocal sensor to measure gasket height immediately after application and leverages the adhesive’s fluorescence for additional monitoring without production delays.

This approach replaces the small-scale manual or semi-automated methods reliant on operator skill with a scalable, repeatable process engineered for volume production. DELO’s proven expertise in high-stakes manufacturing sectors like semiconductor and automotive supports the reliability required for fuel cell sealing, where leaks can cause system failure.

The system is being presented at the Hydrogen Technology World Expo in Hamburg, reflecting the critical role of advanced production systems in fuel cell commercialisation beyond stack chemistry alone.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS