ANDRITZ booster cell line goes live at German EV maker

(Image courtesy of ANDRITZ)

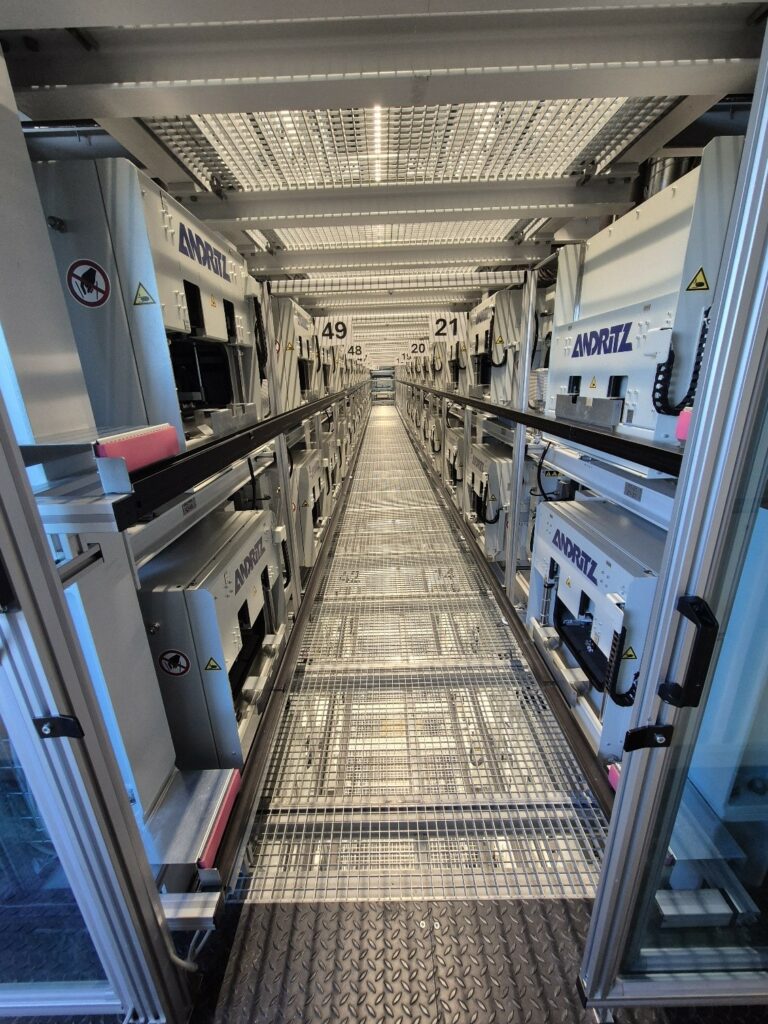

ANDRITZ Schuler has commissioned a 1.5 GW battery cell formation line at a German premium electric vehicle manufacturer’s facility. This marks one of Europe’s largest installations dedicated to booster cell production. The line produces cylindrical cells engineered for high C-rate charging and discharging, an emerging approach as automakers separate power delivery from energy storage in next-generation EV architectures.

Booster cells serve as dedicated power buffers for transient acceleration loads and ultra-fast charging events. They allow the main traction battery to optimize for energy density and range rather than peak power capability. Select premium manufacturers pursue this two-battery strategy to boost charging speeds and performance without shortening primary pack life.

The formation line integrates more than 50,000 channels across 200 chambers, each with power electronics for gigawatt-scale throughput. During formation, where cells complete initial charge-discharge cycles, the system captures over two million data points per second. This enables precise grading and an electrochemical fingerprint for every unit.

ANDRITZ Sovema technology powers the automation, including a Track and Trace system linking production history to performance data. Traceability supports quality control, pack design, field diagnostics, and safety analysis over time.

Measuring 22 meters long, 10 meters wide, and 10 meters tall, the setup uses energy-efficient power electronics to cut losses in extended cycles that span days. Modular design and service strategies sustain uptime as European production grows.

Commissioning aligns with automakers’ push for domestic cell manufacturing amid Asian supply cuts and EU sourcing rules. The unnamed customer’s booster focus points to performance-driven tech over mass-market cost competition.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS