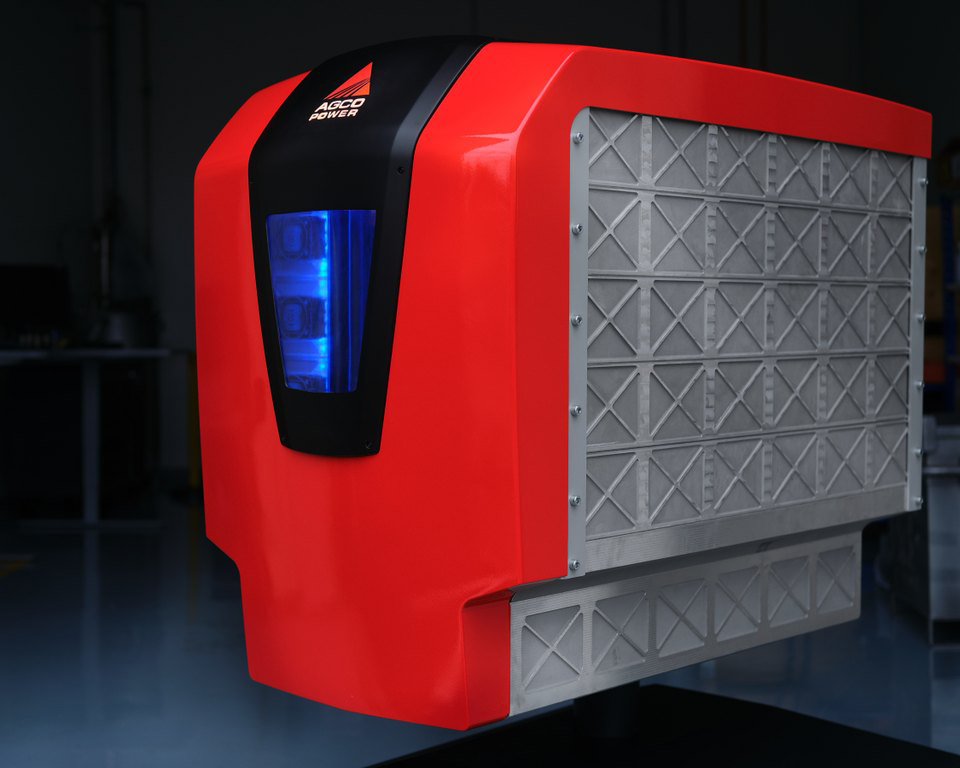

AGCO Power Future Battery Concept brings tailored electric power to next generation farming

(Image courtesy of AGCO Power)

AGCO Power is stepping into the future of farming with its Future Battery Concept, unveiled at Agritechnica 2025 as a prototype energy storage system designed specifically for agricultural machinery. This 150 kWh battery is built around NMC (Nickel-Manganese-Cobalt) chemistry, using approximately 1,400 cylindrical cells to deliver the kind of energy density and durability needed for farm tasks. It is tailored for tractors in the sub-100 kW power range, aiming to provide enough power for common field work while offering faster recharge times that could bring a tractor back to work within 30 minutes via high-power DC charging.

AGCO Power’s battery focuses on meeting farming realities with safety and longevity in extreme conditions, operating effectively in temperatures from −30 °C to +45 °C and fitting within the constrained physical space of agricultural machines. The design reflects the company’s deep experience with tractors, ensuring the battery integrates without compromising the loader, hitch, or other critical attachments that define tractor functionality.

In typical light-duty work such as greenhouse cultivation, orchard and vineyard operations, indoor feeding, and municipal street maintenance, the battery can power 5 to 6 hours of operation between charges. The charging strategy is designed around current farm realities, supporting 50-100 kW charging stations with a 30-minute charge cycle bringing the battery to optimal state, while overnight slow charging at lower power remains practical for daily farm routines.

AGCO Power positions the battery system for light-duty agricultural tasks where zero emissions and quiet operation provide clear advantages, rather than continuous heavy draft work. This targeted approach reflects the company’s pragmatic view that battery-electric tractors currently suit specific power and size classes within agriculture’s diverse operational demands.

The electric drivetrain supported by this battery offers clear benefits such as lower operating costs, quieter performance, almost maintenance-free driveline without oil changes or engine servicing, and zero emissions during operation. Looking ahead, electric implements currently driven via mechanical PTO shafts could draw power directly from the tractor’s battery, opening new possibilities for implement design. AGCO Power views this battery as part of a multi-energy strategy, combining advances in diesel technology and hybrid modules while assessing future chemistries including solid-state batteries and hydrogen, but sees battery-electric power as the most efficient and readily deployable solution for near-term zero-emission farming in suitable applications.

This Future Battery Concept is expected to be production-ready in five to seven years, fitting within AGCO Power’s broader vision to support farming with reliable, economically sound, and fit-for-purpose energy solutions that don’t demand farmers redesign their tractors around the battery, but rather deliver power on agriculture’s terms.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS