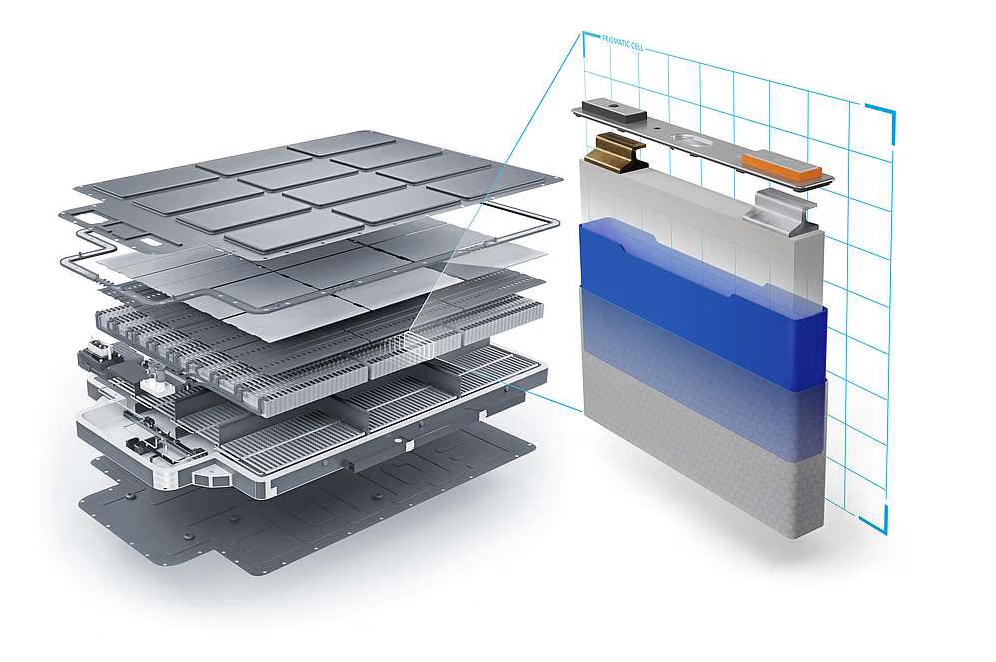

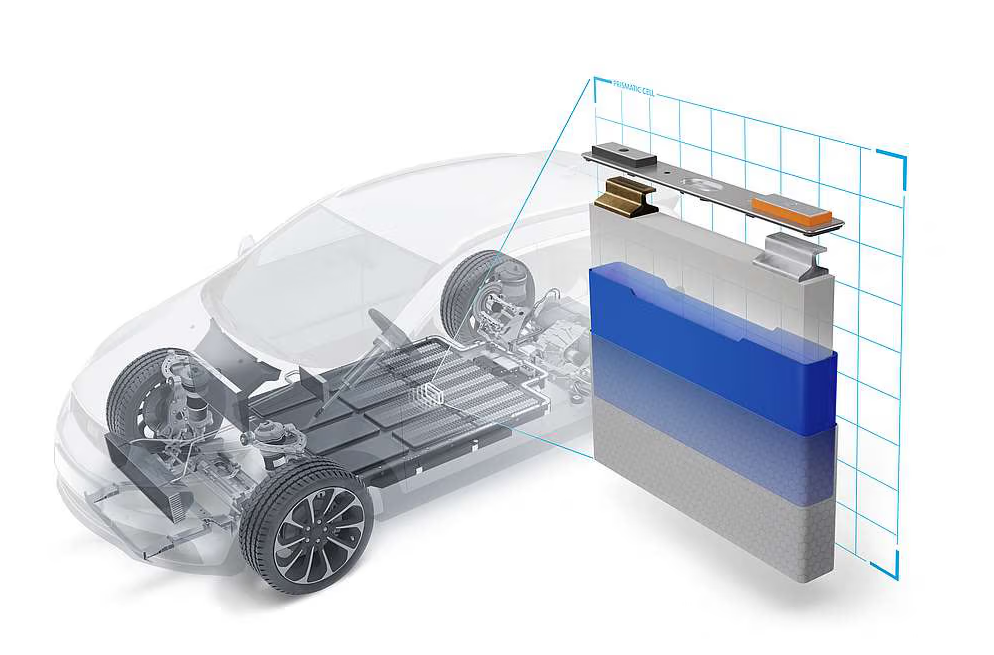

Advanced materials enhance energy density and safety in Freudenberg EV battery solutions

(Images courtesy of Freudenberg)

The rapid evolution of electric powertrains is intensifying the focus on safer, more efficient and longer-lasting battery systems. Freudenberg has developed a set of technologies that address key challenges in cell and pack engineering through advances in materials and component design.

In prismatic cells, performance is strongly influenced by the design of caps and envelopes. Freudenberg combines sealing expertise, engineered plastics and precision stamping to produce components that maintain dimensional stability under load while providing reliable sealing throughout repeated charge cycles. The integration of polymer and metallic elements offers insulation, chemical resistance and mechanical strength, reducing the risk of gas leakage or electrolyte escape and supporting long service life.

Thermal propagation within modules is mitigated by multilayer heat shields engineered to slow or prevent heat transfer from a failing cell to its neighbours. These shields are optimised for low thermal conductivity and resistance to aggressive vapours, enabling stable operation even under abusive conditions.

The DIAvent system provides dynamic pressure management for large-format batteries. Its nonwoven membrane equalises pressure under normal operation to protect housings and seals, while allowing controlled gas release during rapid pressure rise events. Tested in extreme conditions, it prevents deformation or rupture of the pack casing.

Surface durability is addressed by Freudenberg subsidiary SurTec, which develops chemical pretreatments and electroplating solutions for housings and connectors. These coatings combine corrosion resistance, conductivity and thermal-cycle stability, ensuring long-term component performance in demanding environments.

In manufacturing, filtration ensures stable and clean processing across electrode coating, drying, assembly and recycling. Freudenberg’s high-temperature HEPA HTH-1 filter resists thermal degradation while maintaining high particle capture, supporting consistent electrode quality and safe working conditions under elevated loads.

Together, these technologies illustrate an integrated approach to energy density, safety and manufacturability in next-generation batteries. Freudenberg will present its latest developments at the Battery Show North America, booth #5208, from October 7–9.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS