Advanced techniques for battery thermal management fluid selection with Castrol ON

Why Direct Thermal Management?

Effective thermal management of batteries is critical to maximise performance & durability. The first mass market HEVs and EV batteries used passive or forced air thermal management. As vehicle performance requirements have increased most current electric vehicles use a water glycol based thermal management system. As this medium is electrically conductive it must be separated from the electrical components, commonly achieved either using a heat exchanger under the cells or tubes woven between the cells.

This approach is known as indirect thermal management and has several limitations. Firstly, proximity of the thermal management fluid to the cells is limited. This reduces the available heat paths to the fluid which limits the total heat flux rates and biases the heat path to one side or area of a cell leading to high inter-cell temperatures. To achieve higher energy density there is an industry trend towards larger format cells which results in increased volume to surface area ratio and makes cell thermal management ever more challenging.

Since 2017 Castrol has been investigating direct thermal management technology using a dielectric fluid which can be in direct contact with the electrical components. This approach can achieve more uniform inter- & intra- cell temperatures contributing to cell longevity & performance. In addition, it can increase heat removal and enable faster charging.

In 2019 Castrol ON introduced EV Thermal Fluids to the market for direct battery cooling technology and the brand currently offers a range of fluids tailored to meet customer requirements.

The test rig & direct cooled module presented here have been co-developed with a Battery Electric Vehicle Automotive Partner. Direct thermal management was applied to large format cylindrical cells, represented by aluminium cylinders containing heater cartridges, in conjunction with Castrol ON EV Thermal Fluids.

Testing Concept

Castrol have developed an in-house rig to test EV Thermal Fluids in interchangeable battery modules that don’t include live cell chemistry or any combustible materials. Cells are replaced with representative units that feature internal electrical heating to mimic cell thermal behaviour and thermistors to measure surface temperature. The units are carefully engineered to replicate the thermal characteristics of the cells they are representing.

While battery system validation testing normally needs to be completed with real hardware, for the purposes of developing thermal management systems and fluids Castrol has found the thermal rig approach offers several key advantages over live cell testing. Live Li-ion cells are subject to both calendar and cycle aging which makes obtaining precise repeatable results over time very challenging. In addition, cell piece to piece variation reduces test reproducibility and can result in an imbalance of cell voltages within a module over time which further impacts test results. To combat this, a time-consuming cell balancing procedure must be completed regularly which significantly reduces test throughput. Live cells have a finite energy capacity and limits on charge and discharge rate and temperature. This limits the steady state test time and test conditions that can be investigated.

Although rare, the separator within a live cell can fail for several reasons which causes an internal short circuit. This is likely to initiate combustion of the cell materials which can spread to the surrounding cells. The provision of safety systems required to deal with an event of this type considerably increases the cost and complexity of the test facility and recovering from such an event can be expensive and result in significant rig downtime. Using heated representative cells produced from non-combustible materials eliminates this risk.

Castrol ON Thermal Rig

The Castrol ON Thermal Rig has been developed entirely in-house and is shown in Figure 1. It allows for interchangeable model modules, enabling production or 3D printed development parts to be easily integrated and tested.

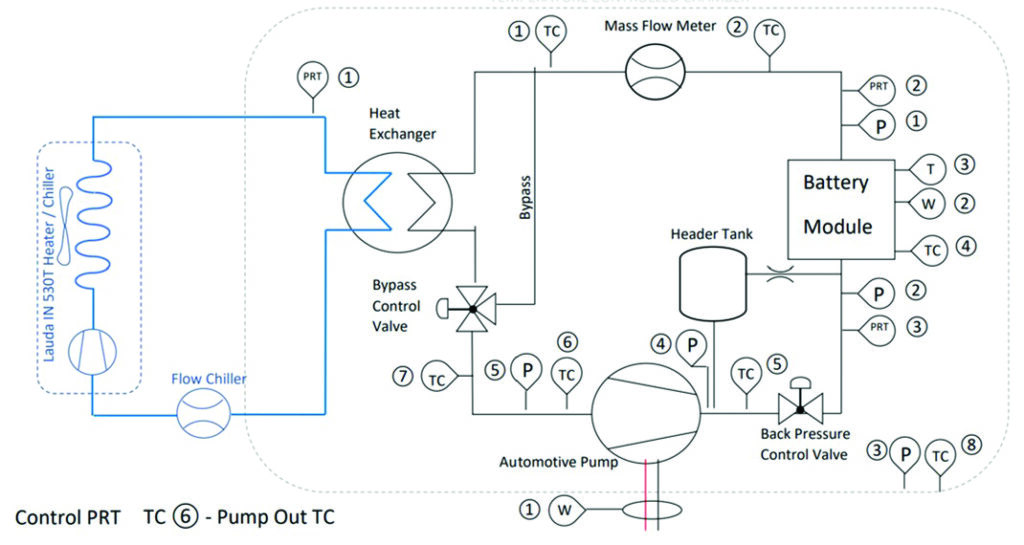

The fluid handing circuit, shown schematically in Figure 2, includes a chiller, heat exchanger, fluid pump, control valves and comprehensive instrumentation to accurately control the boundary conditions of the thermal management fluid delivered to the test module. The rig supports up to 48 heated cells that can be independently controlled, generating heat internally at up to 200W each. Instrumentation includes 12 pressure and 122 temperature channels as well as mass flow meters and pump power consumption measurement. The integrated automation system enables comprehensive testing and system-level analysis with full test cycle control and can precisely emulate transient and steady state vehicle operating conditions. In addition, it controls the temperature of the test fluid and test chamber. The data acquisition system can log at a rate of up to 100Hz.

Heated Representative Cells

While removing live cells from the testing environment offers many advantages the main challenge with the technique is the need to carefully engineer the representative cells to replicate the thermal characteristics of the model they are replacing. This involved first mapping the surface temperature of the real cells under controlled conditions when charged at a range of C rates. The next step was to design an electrically heated version to replicate this performance, supported by simulation models and testing of multiple physical prototype iterations. After manufacture the cells were individually calibrated to determine the heater power required to emulate operation of the real cell at range of C rates. This data was then input into the rig control system.

As previously discussed, temperature measurement instrumentation can be incorporated into the representative cell allowing high fidelity insights into the performance of the battery thermal management design such as intra-and inter cell temperatures. This is typically very difficult to achieve with live cells. In this case 3 thermistors were added to opposite sides of each cell as shown in Figure 3.

As with all components that are in contact with the thermal management fluid, material compatibility must be ensured to avoid premature failure. To this end all materials used in the cell construction including any seals, adhesives and wiring are assessed for compatibility typically using an accelerated aging test.

Conclusions

The thermal rig with heated representative cells developed by Castrol is powerful experimental facility to study the performance of battery thermal management systems and fluids, particularly suited to the pack and module development phase. The approach overcomes many inherent difficulties with live cell testing to produce highly repeatable measurements although significant upfront effort is required to develop and control heated cells that faithfully replicate real cell performance.

In Part 2 of this series, we will discuss how the method was applied in conjunction with simulation models to assess the performance of a prototype direct cooled battery module and how fluid properties affect this.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS