Porsche Cayenne Electric debuts with 850 kW powertrain and next‑gen 113 kWh battery system

(Image courtesy of Porsche)

Porsche has begun series production of the Cayenne Electric, marking the brand’s entry into the premium electric SUV segment with in-house battery manufacturing capability in Slovakia. The Turbo variant delivers up to 850 kW and is built on a flexible line alongside combustion and hybrid Cayenne models at the Volkswagen Group plant in Bratislava, so the EV effectively becomes another derivative in an already high-volume programme rather than a standalone product. Inside, the latest generation introduces Porsche’s largest screen area to date and an upgraded Porsche Communication Management system, while keeping a high degree of trim and feature customisation to avoid alienating existing Cayenne customers moving across to a battery-electric drivetrain.

To support the SUV, Porsche and Porsche Werkzeugbau have established the Porsche Smart Battery Shop in Horná Streda, a dedicated facility focused on series production of the brand’s next generation of high-voltage modules. Processes that began in the prototype environment have been transferred into a tightly controlled industrial flow, with automated stages for cell conditioning, stacking, laser welding, foaming, integration of the cooling plates and end-of-line testing to stabilise quality and throughput. By treating battery modules as a core technology and bringing more of that value chain in-house, Porsche is aiming for tighter control over precision, scalability and long-term product evolution than would be possible with a purely external supply model.

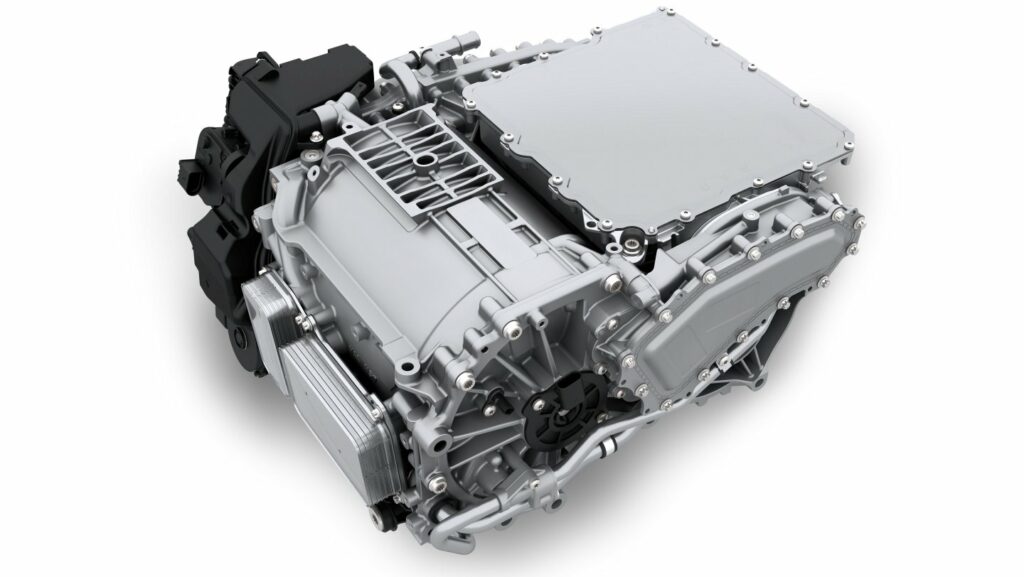

The Cayenne Electric’s energy storage system is built around a function-integrated high-voltage battery with a gross capacity of 113 kWh, using large-format pouch cells and configured for a driving range of more than 600 km. An 800 V electrical architecture underpins charging at up to 400 kW, positioning the vehicle among the fastest-charging SUVs in its segment and helping to narrow the gap between long-distance ICE use cases and EV ownership. Thermal management is central to that strategy: the pack employs double-sided cooling, with plates above and below the cells to heat or cool as required, a layout Porsche presents as a world first that keeps the cells closer to their optimum temperature window while avoiding unnecessary energy overhead.

On the vehicle side, production of the Cayenne Electric starts in a new platform hall at Devínska Nová Ves, where the skateboard-style chassis is assembled and then mated with side structures, roof and closures to create the finished body. Panels are supplied from a highly automated press shop described as one of the most modern in Europe, and the shared line concept means combustion, hybrid and battery-electric Cayennes are all built to a common quality standard. Porsche keeps a permanent resident team on site at the Bratislava plant to handle ramp-up issues in real time and feed operational lessons quickly back into the wider organisation. The platform is expected to underpin additional electrified variants across Porsche’s SUV lineup as the brand scales its battery-electric production through 2026.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS