Fuel cell adhesives

Getting stuck in

Developing adhesives and sealing materials appropriate for hydrogen-based fuel cells and electrolysers is a sticky challenge. Nick Flaherty investigates

Hydrogen is the smallest of all molecules, meaning that the adhesives and sealants used for fuel cells must ensure a very tight seal to prevent diffusion. The materials also need to survive for as long as possible in highly acidic (low pH) environments.

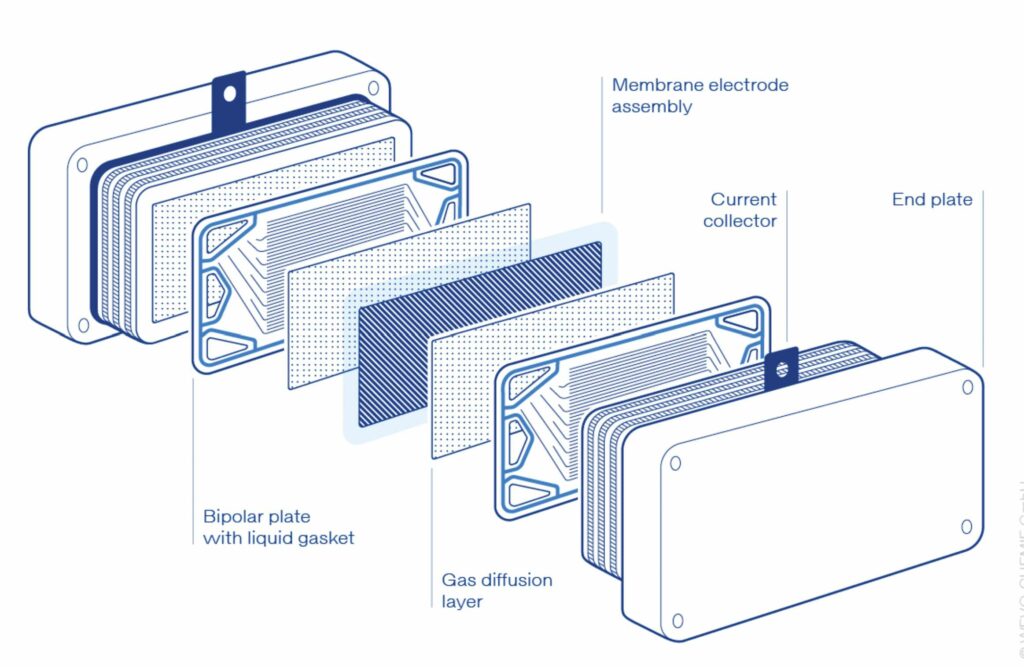

Fuel cells consist of several functional layers that can differ both in terms of the materials and components used and in terms of the working principle. One of the most common types, which is currently being widely researched because of its suitability for the automotive sector, is the Proton Exchange Membrane (PEM) fuel cell.

The bipolar plates of the PEM fuel cell ensure a steady supply of hydrogen to the cells and simultaneously control the release of electrical energy, but because hydrogen is flammable and can form explosive mixtures (oxyhydrogen) in an oxygen-containing atmosphere, reliable sealing of the individual cells is essential.

The sealing materials must be not only highly impermeable to gas but also resistant to challenging conditions such as continuous high temperatures of up to 120 C or acidic environments from the hydrogen. If the bipolar plates have tolerances due to manufacturing, the resulting uneven pressure distribution on the sealing materials must be compensated, especially while the stacks are being pressed.

To date, preformed inlay gaskets have been used for this compensation. However, owing to the need to insert them manually on both sides of each bipolar plate, they are unsuitable for automated production in high volumes, as required in automotive fuel cell design in particular. There is also a risk that a bipolar plate might become detached during stacking and no longer seal effectively. Commercially available, addition-curing silicone liquid gaskets have drawbacks, such as their generally high gas permeability and their poor adhesion to most substrates.

Instead, a chemically resistant, two-component material based on polyurethane and silicone can be applied as a liquid gasket that is formed inplace. This has advantages for the manufacture and operation of fuel cell components.

One of the silicone-based products exhibited a very low hydrogen permeation coefficient of about 130 E-8 cm²/s after a measurement time of 16 hours, which compares favourably with the figure of 500–1000 E-8 cm²/s for addition-curing silicones. Moreover, the adhesion to metal surfaces also improves.

Polyurethane sealants, which have similar thermo-mechanical properties to silicones, have even lower hydrogen permeability, depending on the Shore hardness setting. The permeation coefficient varies between about 30 and 70 E-8 cm²/s, also after a measurement period of 16 hours. These sealants adhere significantly better than silicones to the different substrates of bipolar plates. This prevents the seal from detaching either in the course of the manufacturing process or during stacking, so that loss of the sealing effect is no longer an issue. Much faster curing is also possible compared with silicones – a major asset when it comes to automated production of high volumes.

(Image courtesy of Wevo Chemie)

Stacks

The polyurethane-based products can also be used as adhesives for other applications, both within the fuel cell stack and in the balance of plant (BOP) that is the surrounding system, as a result of the good adhesion properties. As well as bonding the entire stack together, it is possible, for example, to simultaneously join and seal the two half-shells that form the bipolar plates using customised, soft and elastic polyurethanes. For metallic bipolar plates, this joining method can be employed as an alternative to laser welding; with plates based on graphite/polymer composites, durable bonding is key.

The anode recirculation blower or the air compressor installed in the air circuit are other possible applications in the BOP. In the latter case, the epoxy resins and silicones enable potting of the stator for the drive motor. By optimising the thermal conductivity and crack resistance of the materials, the forces produced during rotation are compensated and the heat generated is removed in a targeted way. Special thermally conductive, polyurethane potting compounds and silicone gels for the power modules are used for power electronic components such as DC–DC converters, onboard chargers and control units.

Humidifiers

The humidifiers used in PEM fuel cells need to withstand high levels of humidity as well as exposure to heat and chemicals. The materials used in these applications are therefore of key importance for their safe, reliable operation and efficient production. To meet the strict requirements, it is usual to use adhesives, sealants and potting compounds based on polyurethane, epoxy resin and silicone, which not only provide gas-tightness and hydrolysis resistance, but also need to have high ion purity and low content of volatile organic compounds (VOCs) to reliably protect the sensitive fuel cell membrane. The materials also need to have individually adaptable parameters for both semi- and fully automated manufacturing processes.

In PEM fuel cells, humidifying the incoming air is crucial for maintaining the conductivity of the membrane – and thus, the efficiency of the entire system. This task is performed mainly by flat-sheet membrane and hollow-fibre membrane humidifiers.

Flat-sheet membrane humidifiers often consist of several hundred layers of membrane and spacer materials, which must be reliably and permanently bonded together to form a stack. In many cases, this stack is additionally glued into the housing of the humidifier or partially encapsulated to achieve a gas-tight seal.

Hydrophobic adhesives and potting compounds meet these requirements. The water-repellent polymer backbone also makes them suitable for use as hydrolysis- and temperature-resistant sealants. The 2-component (2K) polyurethanes and silicones adhere very effectively to the substrates used most commonly as spacers, including polyolefins, polyphenylene sulphide (PPS) and fluorinated membrane materials – the bonding of which has been a challenge up until now.

In humidifier applications, the high ion purity and low levels of VOCs rule out damage to the sensitive, ion-selective polymer membranes and the associated drop in performance. High hydrolysis resistance at temperatures up to 100 C is ensured by the special composition of the customised products.

Another characteristic of the formulations is the low glass transition temperature, which ensures high tear resistance, long-lasting elasticity and resistance to temperature changes – essential when cold-starting fuel cell systems.

In hollow-fibre membrane humidifiers, bundles of tubular membranes are potted into a support tube at both ends – a principle familiar from water filtration. The resins must penetrate between the hollow fibres and ensure sufficient wetting of the bundle without clogging the individual fibres.

For this reason, potting compounds have been designed for optimal exothermicity. The heat generated during the reaction between the resin and hardener is controlled, thereby effectively preventing oxidative damage to the sensitive membrane tubes. At the same time, the 2K polyurethane systems are hydrophobic and prevent a reaction with the moisture contained in the membrane material and consequent bubble formation.

For processing and application, the properties of the adhesive such as viscosity and pot life can be customised to meet individual requirements. Curing usually takes place at room temperature, but to accelerate manufacturing cycles, it is also possible to use thermal curing in a convection oven or via infrared radiators.

The two-component systems can also be used for other applications in humidifiers, such as for sealing and bonding housings, for seals on water inlets and outlets, for sealing and bonding bypass valves and for creating internally sealed zones.

(Image courtesy of Quantica)

UV curing

High-performance, light-curable materials streamline bonding, masking and sealing steps in fuel cell manufacturing. The materials can be formulated for assemblies exposed to elevated temperatures and aggressive operating environments, maintaining dimensional stability and adhesion when used with metals, ceramics and composite substrates.

The instant UV and visible light curing minimises thermal load, and enables precise control of bond-line thickness and gasket profiles, improving process consistency and repeatability.

These materials are formulated without solvents to prevent contamination of active cell layers and reduce outgassing, supporting stable long-term cell performance, and they are compatible with multiple operations, meaning that the same curing platform can be used for structural attachment, edge sealing and protective masking. This simplifies process design and reduces cycle time through an integrated approach that supports automated assembly and quality validation.

These capabilities help engineers increase throughput, and maintain mechanical and chemical reliability in demanding fuel cell applications.

Applying the material

Fuel cell manufacturers face a key challenge in sealing individual cells, which is a slow, energy-intensive process that directly affects the stack’s lifetime and reliability. Traditional methods involve long curing times and complex workflows, making them unsuitable for industrial-scale production.

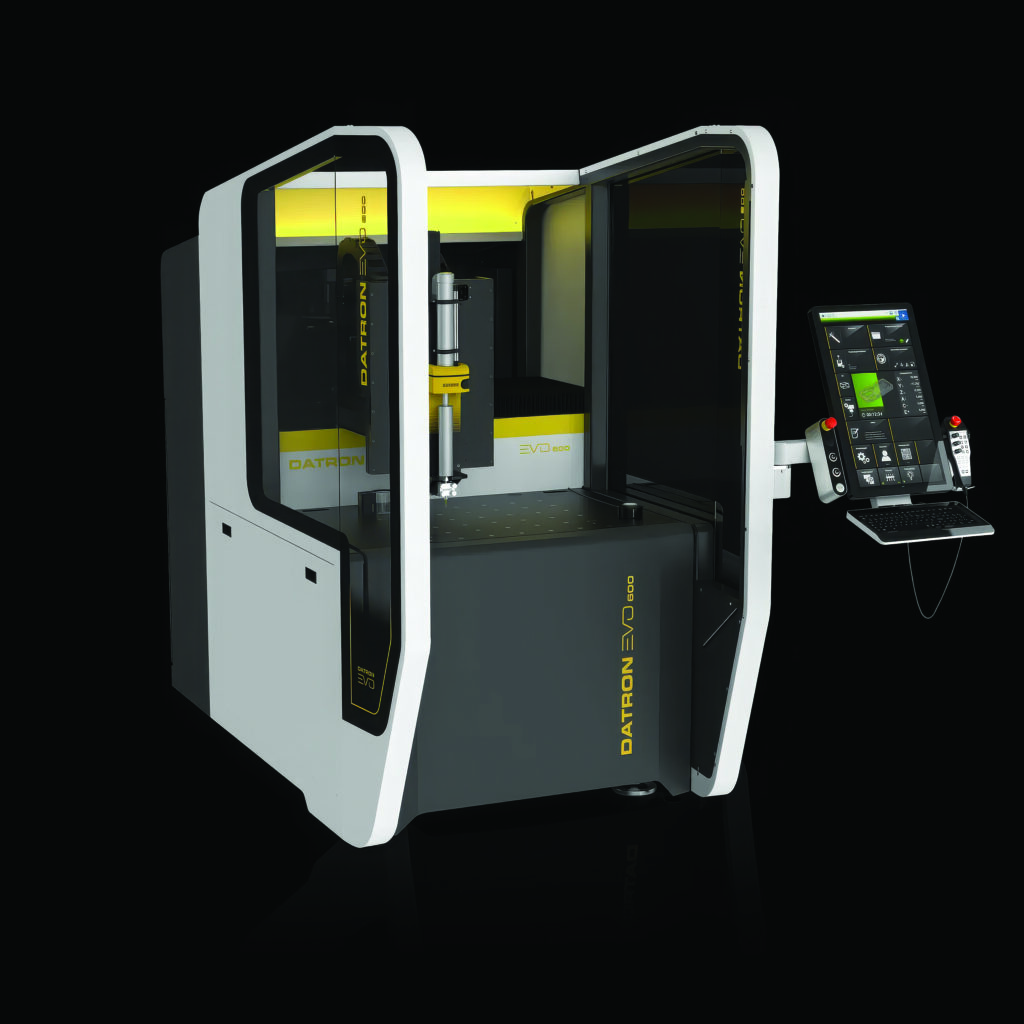

Delo and Datron have jointly developed a fully automated, high-speed sealing system. This combines Delo’s fast-curing liquid sealant and UV technology with Datron’s high-precision dosing system.

At the heart of the system is Delo’s Photobond SL sealant, which has been developed specifically for fuel cell applications. This is applied directly as a liquid gasket and cures in seconds under UV light.

The process is enabled by the Datron evo 600 system, capable of dispensing at up to 50 m/min. The volumetric dosing control ensures a consistent bead profile, even at start and stop points.

Two key features ensure the inline quality assurance: an integrated confocal sensor that measures bead height immediately after dispensing, and the fluorescent properties of the sealant, which allow optical quality checks in real time with a closed-loop monitoring system. Together, these elements create hundreds of precisely sealed fuel cells ready to be assembled into a high-performance stack.

The fast curing provides high-speed assembly, with high chemical resistance against sulphuric acid and deionised water. This gives the maximum design freedom thanks to liquid application with volumetric dosing for consistent, uniform beads.

(Image courtesy of Quantica)

Inkjet printing

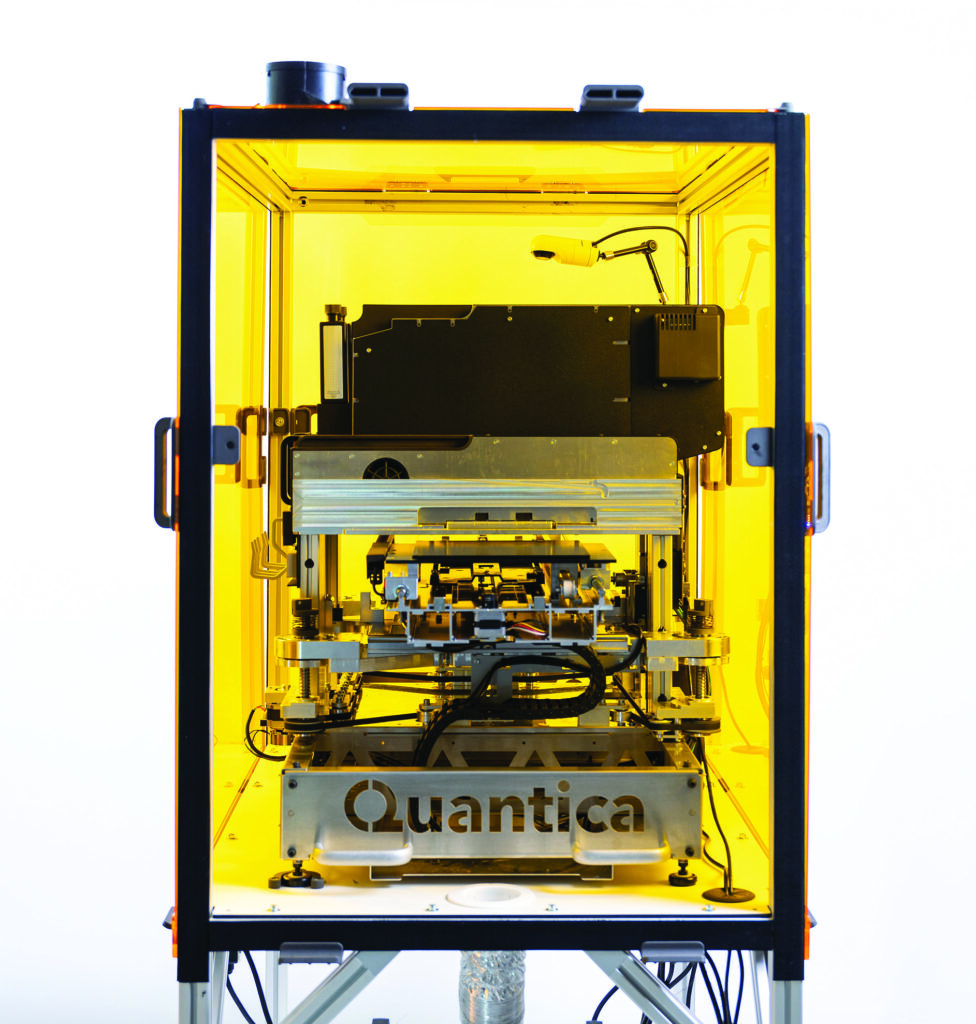

Another way to apply the adhesive and other materials is using inkjet printing technology to provide accurate dispensing of the adhesives in complex patterns.

“This is a digital replacement for dispensing systems that scales more easily to large-scale manufacturing,” said Ben Hartkopp, founder and head of research and IP at Quantica in Germany. “One of the first ultra-high-viscosity applications was for printing the channel plates in fuel cells.”

This used a UV-activated material from Henkel as an adhesive and gasket, providing sub-millimetre placement. “With an inkjet, you can print exactly to a certain distance to the edge, so that the material exactly conforms to the geometry, by adjusting the drop density on the fly, even with batch variations, so there is controllability,” he said.

To do this requires a different type of printing technology.

“We built our own print head and our own actuators,” he said. This provides 8000 drops/nozzle (8 kHz frequency) with 96 nozzles in the print head. The print heads can be stacked, which gives a single pass with inline speeds of 1.0–1.2 m/s and higher if more print heads are used, so there is no throughput bottleneck for printing complex geometries. The drop sizes range from 250 up to 600 pl and Quantica can easily vary the nozzle size, he said.

“We use laser ablation for the forming of the nozzles, and the actuator is agnostic to the nozzle size – so we can go down to 30 up to 90 μm – depending on the fluid characteristics,” he said.

The print head uses an actuated channel with forced ejection – so there is no specific fluidic geometry – rather than using a resonant frequency that is droplet-size dependent.

“This means we have a larger deflection that pressurises an area around the nozzle so we can change the nozzle size easily,” said Hartkopp. “This forced ejection is more stable for the edge issues and across batch variations – that’s a huge fundamental advantage, particularly for adhesives.”

This also increases the potential for adding larger particles up to 9 μm.

Quantica designs the print head, which is manufactured by a partner. Quantica has developed a dispensing system that can be used for evaluation that includes UV LEDs for curing the adhesive if necessary and can be integrated into the equipment. The print heads can also be used by integration partners.

“We work with integrators and we have developed our own material supply system with all the electronics that can be integrated into production lines. We also supply the print engine that can be integrated with any trigger signal system.

“With the system integrators, we talk about the spacing of the initiators for the UV for the epoxy to activate, but here you need to look at the time delay and the speed of the line. We have 365 and 405 nm wavelength UV available because we use them internally, but they might not be up to spec for line speeds of 2.8 m/s, but we can also use off-the-shelf UV units.

“We provide some specific fluidic properties as a reference – we have heating integrated into the print head to reduce the viscosity from room temperature – if we get it down to 250 mPa s, then we can inkjet it with a 9 μm particle,” he said. “We prefer higher surface tension but we have printed 20 mN/m, we have printed liquid metal, and we can print Newtonian and non-Newtonian materials.

“Most of the materials typically have a visco-relaxive response, so the higher the frequency, the more like a solid they perform – that is a problem for traditional inkjet printers. These are highly particle-loaded or resins with large molecular weights or aqueous polymers with a high concentration.”

Another advantage of the inkjet printing technology is that it does not need tight integration with the material supplier.

“We can be somewhat independent of the type of material, but it helps a lot if there are discussions on batch variation – we can print the majority of materials we get, but some need engagement with the supplier; for example, if there is foaming or certain dilutions or stabilisation agents that are needed for particle loading,” said Hartkopp.

“We need around a litre for the analysis in a couple of days, and implement in less than a week if necessary – that gives the custom a lot more confidence.”

At the moment, the system uses one material per print head, but research is continuing on the next-generation system that could be able to handle multiple materials per print head, says Hartkopp.

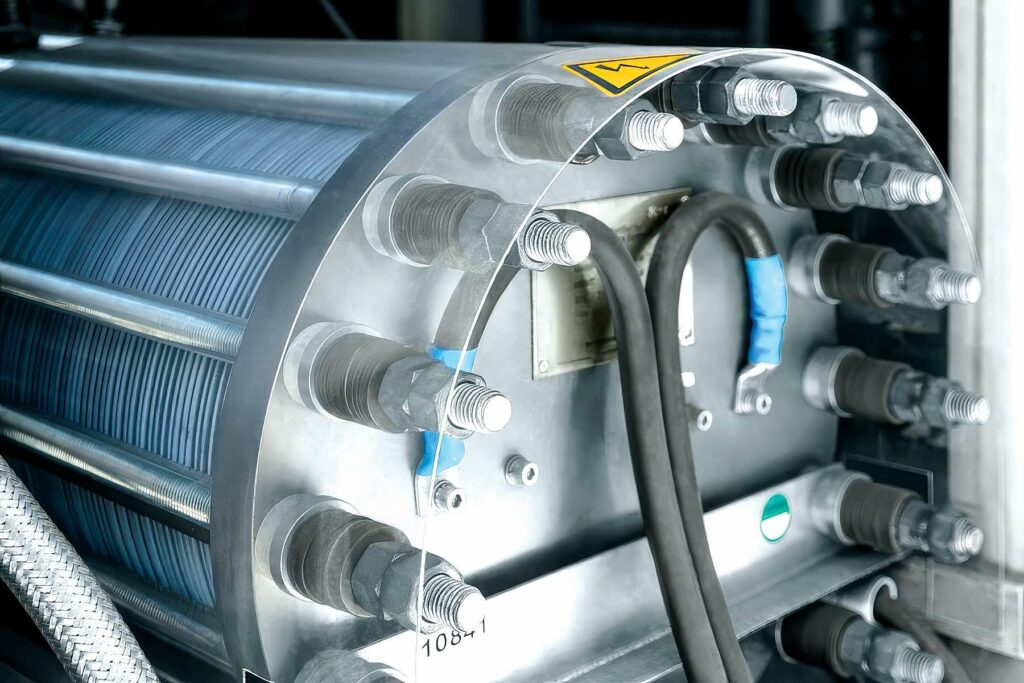

Electrolyser

The low hydrogen permeation coefficient of only 3–4 E-8 cm²/s means customised, tough polyurethane adhesives are also suitable for various components involved in the hydrogen production process.

Alkaline electrolysers need adhesive systems with even higher chemical resistance than is afforded by polymer membrane technology because this widely used type of electrolyser works with an aqueous potassium hydroxide solution (30–35% KOH) at 90–95 C as its electrolyte. The majority of organic adhesive and sealing systems are not able to withstand such conditions permanently. A specially optimised, highly cross-linked and chemical-resistant epoxy resin, which in its thixotropic form is suitable for applying adhesive beads, is one of only a few products currently available capable of meeting these requirements.

Automated production of an electrolyser stack with capacity of 1 MW is around six times faster than manual assembly. However, the task of sealing the bipolar plates, the individual cells and the stack as a whole poses a major challenge. If complete or partial automation is to be achieved, the flat gaskets and O-rings often used must be replaced with an alternative sealing method, says Andreas Arlt, business development manager at Wevo Chemie.

Wevo has developed materials that can be applied as liquid sealants and adhesives. These bring three key benefits: a high degree of chemical resistance, low hydrogen permeation and good adhesion properties. All three have been verified by leading research institutes and in customer projects. Polyurethanes, epoxy resins and silicones from Wevo open up new possibilities for alkaline and Anion Exchange Membrane (AEM) as well as PEM electrolysers, as in the design of stacks, for example.

In alkaline electrolysis systems, the hot potassium hydroxide solution (30–35% aqueous KOH solution at a temperature of 80–90 C) used as the electrolyte creates challenging ambient conditions. Newly developed materials, based on modified polyurethanes, epoxy resins and silicones, enable sealing, stack design and automated production for this technology. The materials are also increasingly being used for AEM electrolysers, where the requirements are high despite the much lower concentration of the KOH solution.

The new epoxy resin system can be used as an adhesive and sealing material for bipolar plates, individual stack cells and the entire stack with high chemical resistance. This has been confirmed by immersing test specimens in a 35% aqueous KOH solution at 90 C for several weeks, and by investigations carried out by the Welding and Joining Institute of RWTH Aachen University.

The subsequent examination showed a very low weight loss of <0.8% and only a very slight change in the Shore hardness of ±0.2 units. In addition, no visual change to the surface of the test specimen could be detected, which was also verified by laser confocal microscopy. Furthermore, the materials have very low gas permeability: the hydrogen permeation coefficient measured at the hydrogen and fuel cell centre ZBT in Duisburg is just 0.3 10E-8 cm²/s for the WEVOPOX VP 414 epoxy resin.

The adhesives and sealing materials also provide very good adhesion to the various metal substrates that are used as electrodes and membranes, such as stainless steel or nickel, as well as to various plastics.

Other low-viscosity epoxy resin systems are also suitable as potting compounds in this area thanks to their high chemical resistance and viscosity properties, opening up new customisable options for the design of individual cells and the entire stack. Cell components such as electrode or membrane foils can be connected to the frame seamlessly and completely tightly without there being any need for additional gaskets or adhesives.

Wevo is also currently working on special hydrolysis-resistant polyurethane resins as potential sealing materials for alkaline and AEM electrolysers. In initial ageing tests in KOH solution, the WEVOPUR materials demonstrated good resistance properties, said Arlt.

“We are collaborating with various research institutes and industrial partners with a view to offering more solutions in this area in the future,” he confirmed.

(Image courtesy of Wevo Chemie)

Electrolyser materials

The expertise from fuel cells has also been used for PEM electrolysers to seal the components of the electrolyser stack. Addition-curing silicones or modified polyurethanes have been developed for this with thixotropic silicone systems offering very high chemical resistance levels in the highly acidic conditions.

The elasticity and elongation of these materials can be adjusted over a wide range, allowing individual adaptation to the structure and operating pressure of the respective electrolyser. Elastomer materials with a Shore A hardness in the range of 60–70 include the soft and elastic silicone sealant WEVOSIL 28001 and the thixotropic version WEVOSIL 18001 T.

The special chemical composition of the silicones allows a very low level of hydrogen permeability. The hydrogen permeation coefficients measured at ZBT are approximately 130 10E-8 cm²/s for WEVOSIL 28002 and around 220 10E-8 cm²/s for WEVOSIL 28102. Addition-curing silicones are typically in the range of around 500 to over 1000 10E-8 cm²/s.

The silicone products and the modified polyurethanes are an alternative to the flurorubber materials frequently used for inlay gaskets. These flurorubber materials include per- and polyfluoroalkyl substances that are being phased out and so the material will eventually be replaced.

During automated production, the materials are applied as a liquid using a dispensing or screen-printing process and hardened as a CIPG (cured-in-place gasket) or FIPG (formed-in-place gasket) prior to the stacking process, depending on customer requirements.

To enable the silicone materials to be used with the faster of these two processes (screen-printing), the pot life has been modified to at least 24 hours at room temperature, which means that the materials can be used on the screen and screen-printing machine without the need for intermediate cleaning. Fast curing is then carried out either in a convection oven at temperatures of 100–140 C or using near-infrared radiators. The two curing methods can also be combined.

The long pot life allows the soft and elastic isocyanate-free polyurethane sealant to be applied using the screen-printing process. Wevo is developing a more reactive version, with a shorter pot life and curing time, that can be used with the dispensing process.

Conclusion

Adhesives and sealing materials are a key challenge for hydrogen-based fuel cells and electrolysers. The same dispensing techniques that are used for adhesives can be used with curable liquid materials for gaskets, simplifying the supply chain and production line. The latest inkjet technology can also provide more accuracy in dispensing and flexibility in the choice of materials, as well as the ability to handle variations in batches, which is a key consideration on the production line.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS