The Battery Show North America Show Report

Powering innovation

Peter Donaldson explores the highlights from Detroit’s leading advanced battery and EV event in North America. Here, he tells us why

Held at the Huntington Place exhibition centre in Detroit, Michigan, from October 6–9, 2025, The Battery Show North America brought together more than 21,000 attendees, 1300 suppliers and 150 speakers, providing an opportunity for the industry to peruse a wide range of new products including electric drivetrains, battery manufacturing and testing technology, thermal protection materials, adhesives and dispensing systems and more.

Here is a selection of the attention-grabbing offerings.

Bonfiglioli presented its 601 F drive system, which is the result of a focused, decade-long evolution in electrifying counterbalance forklifts, according to electrical engineer Mattia Buscherini, the company’s North America e-mobility solutions sales manager. As part of the 600 F series, this system is engineered specifically for the demanding material handling market, with the 601 F model designed for forklifts with a lifting capacity of up to 2 metric tons.

The core of the 601 F is a wheel hub design, where each wheel is powered by a dedicated gearbox and electric motor. A key technical challenge addressed is operational noise, critical for indoor warehouse environments. Bonfiglioli tackles this at the source: the gearbox’s first reduction stage. “The specific first reduction stage is a helical gear,” explains Buscherini, “and this allows the gear to have more surface area and so the noise level is lower.” These helical gears are further refined with a super-finished machining process to enhance quality and further reduce acoustic emissions.

System integration is another cornerstone of the design. Bonfiglioli designs and manufactures both the gearbox and the AC induction motor, which makes it easier to achieve a compact, optimised solution. This control over the entire drive allows for precise management of tolerances and design features, resulting in a quiet and highly efficient system, Buscherini notes. A significant differentiator is the placement of the parking brake. Here, Bonfiglioli departs from the de facto industry standard of integrating wet disc brakes into the gearbox, which generate heat losses and penalise efficiency. “In the Bonfiglioli design, we decided to install the brake on the back of the motor. We have an electromagnetic parking brake with a dry disc, so that it doesn’t impact the efficiency of the solution.” This is a key element of their product customisation, he adds.

The drive system is also future-proofed for the industry’s transition to Automated Guided Vehicles (AGVs). Bonfiglioli offers customers the option of integrating additional sensors into the 601 F, allowing the same hardware to be used in both manually operated and automated vehicles. This approach also extends to forklift steering drives, creating a unified propulsion and steering solution from a single supplier.

Addressing the motor technology itself, Buscherini confirms the current market standard is the AC induction motor because of its competitive price and decent performance. However, he highlights two main design challenges: space constraints and the relentless pursuit of higher efficiency. The integrated design philosophy directly addresses the spatial limitations. To boost efficiency, Bonfiglioli co-engineers motor windings with customers to optimise performance at the operating points that are used most frequently. The resulting energy saving can translate into a smaller battery or a longer operating time.

Looking ahead, the company is actively developing permanent magnet motors for this application. These offer superior power density and potential efficiency gains, and Bonfiglioli’s engineering team is preparing to support with prototypes, calculations and testing. While inverter technology is sourced from partners, the company works closely with them, providing detailed motor specifications to ensure optimal system performance, ensuring the 601 F drive system remains adaptable as forklift technology evolves.

(Image courtesy of Frenzelit)

Frenzelit showcased its advanced novaVolt aerogel-based intercell insulation material, presenting a sophisticated solution engineered to limit thermal propagation in next-generation battery systems. Designed primarily for prismatic and pouch cells in high-voltage applications, novaVolt takes on the critical safety challenge of preventing thermal runaway spreading between adjacent cells.

The material’s performance stems from its specialised composition and multi-faceted approach to heat transfer inhibition. Wolfgang Wirth, director of advanced development, detailed its makeup: “The main materials that novaVolt consists of are aerogel of course at approximately 45%, and most of the rest is silica fibre, which has a working temperature of 1000–1100 C and can withstand 1200 C in cases of thermal runaway. This silica-fibre-reinforced aerogel matrix is engineered to attack heat transfer through conduction, convection and radiation.”

Thermal conduction through the solid material is minimised by the intrinsic nanostructure of the aerogel. The points of contact between the aerogel nanoparticles are exceptionally small, drastically reducing the solid conduction pathway. “In the aerogel, the surface area over which the particles contact each other is very small, which keeps thermal conductivity very low,” explains Wirth. This very low effective contact area severely limits heat transfer via conduction within and through the material. Furthermore, the encapsulated air within the nanoporous structure suppresses convective heat transfer.

To address radiant heat – a dominant mode of energy transfer at high temperatures during thermal runaway – novaVolt incorporates specialised infrared-absorbent additives. The enormous internal surface area of the aerogel, combined with these additives, reflects and absorbs infrared radiation internally. Christian Kraus, head of mobility sales, elaborates: “The heat radiation will be reflected in the aerogel particles themselves, and partially reflected back or deflected to the side. So, the portion of the heat radiation that goes straight through the material is minimised.” This multi-barrier approach results in a measured thermal conductivity between 35 and approximately 90 milliwatts per metre-Kelvin across a 200–600 C range, substantially lower than that of mica-based alternatives.

Beyond its thermal performance, novaVolt is engineered for practical integration, safety in production and ease of handling. “Our material is nearly without any dust,” Wirth notes, which is a key differentiator from conventional dusty aerogels. Its compressibility is also uniquely tunable via a proprietary lamination process, allowing it to accommodate cell swelling without becoming over-compressed, which would degrade its insulating properties. This allows engineers to tailor the material’s pressure response precisely to accommodate the specific swelling behaviour of different cell chemistries and formats, ensuring consistent thermal protection throughout the battery’s lifecycle.

Frenzelit is targeting the emerging OEM demand for ‘prop stop’ or zero thermal propagation, indicating the material’s strategic relevance. “OEMs are planning to use that material in their next-generation batteries. Start of production will probably be in the 2028 to 2030 timeframe.” The material is beyond the lab stage, with serial production readiness planned for 2026.

By combining ultra-low conduction via minimised solid contact, effective radiant heat reflection and absorption and adjustable mechanical properties, novaVolt represents a technically nuanced and production-ready barrier against thermal propagation.

(Image courtesy of IKA)

IKA is addressing one of the most capital- and energy-intensive steps in battery manufacturing with its CONTERNA LAB, which is a specialised continuous kneading machine for dry electrode production. Unlike conventional methods that rely on liquid solvents to create a slurry for coating, the CONTERNA LAB is engineered for the promising dry process, which eliminates the need for massive drying ovens and solvent recovery systems.

“Customers are moving to dry electrode processing because they don’t want to use liquid solvents such as N-Methyl-2-pyrrolidone (NMP), which come with several health, safety and cost drawbacks,” explains Juergen Lehmann of IKA. “They want to save a lot of money, especially in energy costs and investment costs.” The dry process uses a fibrillating binder, typically PTFE, which transforms from a white powder into a network of microscopic fibres that bind the active and conductive materials together. Other polymer binders which may be used as replacements for the PTFE in the future are in the r&d stage.

The CONTERNA LAB has a modular, multi-chamber design, enabling a range of innovative features. Unlike a traditional extruder, it features a series of individual kneading chambers, each with its own drive. This architecture provides unparalleled process control and flexibility. “Each chamber has an individual drive allowing it to run with a different speed or even different turning direction of the kneading tools,” Lehmann says. This enables operators to tailor the process stage by stage; beginning with gentle mixing tools to homogenise the dry powders before transitioning to high-shear kneading tools in subsequent chambers to initiate and control the critical fibrillation of the PTFE binder.

This precise control is further enhanced by real-time monitoring. Each drive is equipped with torque measurement, which Lehmann identifies as a key indicator: “We realised that the torque perfectly correlates to the degree of fibrillation.” As the material transforms from a powder to a doughy mass, the torque profile provides a clear signature of the process’ progress.

A standout feature for r&d is the live process visibility. IKA’s team developed a transparent cover that remains clear even after hours of processing, allowing for direct visual observation to help inform decisions on how to refine the process. “You can adjust certain parameters and immediately you see what happens in the machine, and by this you gain a great increase in process understanding,” he says. This live monitoring is a significant advantage for optimising complex recipes.

The system is designed for “highly viscous pastes, semi-dry or dry materials, which change their internal structure by energy input utilising the mixing tools. In addition, there is an optional temperature control via the mixing chamber’s double jacket,” Lehmann notes. The scalability from the lab-scale CONTERNA LAB to industrial-scale machines is straightforward, relying on consistent tool design and operating parameters, he says. The system provides a flexible and controlled continuous mixing solution, serving as a vital tool for de-risking and scaling-up more efficient battery manufacturing techniques.

(Image courtesy of Maccor/AES)

Maccor promoted its Fusion battery cell testing system, a customisable turnkey solution that comes with environmental chambers and fixturing from AES integrated with Maccor’s cyclers. The result is a unified, plug-and-play system for laboratories focused on accuracy, safety and scalability.

Unlike piecing together a standalone thermal chamber with a rack of testers, Fusion provides a single, cohesive unit, according to Mike Sandoval from Maccor. “The biggest advantage is that you’re getting one piece of equipment that’s integrated versus multiple pieces of equipment that you then have to integrate yourself, and there could be a lot of pitfalls and a lot of resources used up in that.” This approach is intended to save significant engineering time and effort by delivering a pre-validated solution directly to the customer.

Safety and channel independence are paramount in battery testing, and the Fusion system addresses these through a multi-layered strategy. The Maccor tester itself incorporates safety features that monitor voltage and temperature, allowing it to shut down an individual channel or the entire system. This is complemented by the AES safety chamber, which is engineered to mitigate cell failure events and prevent propagation. Haylie Batres from AES details the two companies’ proactive philosophy, stating: “We go for mitigating the battery events as opposed to just reacting when they happen, protecting the person outside of the chamber.” Key to this is a special fire-resistant laminate board made from FR4 glassfibre–epoxy composite that localises any incident, often requiring only the replacement of one or two cell holders rather than causing widespread damage. An integrated exhaust system further ensures any fumes are vented safely outside the facility.

Sandoval emphasises that the test channels exhibit extremely low drift over temperature and time, adding that this results from the use of high-end components and thermal compensation techniques. This ensures robust data integrity, especially critical during sensitive tests like open-circuit voltage measurements at very low currents. Maccor recommends that its testers are calibrated annually, and some customers do that more frequently. However, Sandoval reports that the need for adjustment is rare. “We’ve actually seen systems with four or five years in the field that are still on the original calibration and they’re all within spec.”

Scalability and serviceability are also central to the Fusion platform’s design. On the Maccor side, test channels are modular, allowing customers to start with a partial system and add more channels as their testing needs grow. The AES chamber offers significant configurability, supporting different cell formats and amperages. “You can either have 16 channels of 200 A cells or you could have eight channels of

400 A cells, says Batres. “You can change the holders themselves to support prismatic, cylindrical or pouch cells in horizontal or vertical orientation.” This adaptability ensures the system can evolve with a lab’s research and development goals without requiring a complete overhaul.

Furthermore, the close partnership between Maccor and AES streamlines support, eliminating the finger-pointing that can occur when dealing with multiple vendors. “If there’s something going wrong, we jump on the call right away and get to the bottom of it.”

(Image courtesy of PVA)

Highland Plastics showed its Kelvinite family of flame retardant (FR) materials for use in batteries to help contain thermal runaway events. The company has a focused materials science strategy, developing a core halogen-free FR polypropylene and a suite of advanced composite prototypes that define a path beyond conventional solutions.

The foundational material of the Kelvinite family was K2200, a halogenated FR polypropylene originally engineered as a US-made alternative for thin-gauge, high-voltage electrical insulation. While K2200 was effective, when halogenated materials burn, they release corrosive and toxic gases, including dioxins, which pose significant health risks and cause long-term environmental damage. Historically, the main challenge with halogen-free flame retardants has been a trade-off in performance or cost. They can sometimes be less efficient than their halogenated counterparts, requiring higher loadings of alternative additives to achieve the same level of fire resistance.

“The market required a halogen-free solution that did not compromise on the stringent FR performance needed for modern electronics and battery systems,” says Ben Simmons at Highland Plastics. This need catalysed the development of K2100, a halogen-free FR polypropylene launched in 2024.

K2100 offers robust performance at thin gauges, from 0.125 to 1.5 mm. The material’s efficacy is rooted in an intumescent mechanism; when exposed to direct flame, it self-extinguishes by forming a thick, insulating char layer. This carbonaceous barrier resists flame penetration, effectively shielding more vulnerable substrates and components. This characteristic, combined with the inherent processability, chemical resistance and superior dielectric strength of polypropylene (demonstrated by a comparative tracking index (CTI) of greater than 600 V), established K2100 as a versatile and high-performance base polymer.

Initial customer demand identified a specific need to replace traditional mica sheets used as thermal barriers. Highland Plastics responded with a series of engineered prototype composites that demonstrate tangible solutions to key failure modes. The K2500 blast shield composite, for example, is a laminate of K2100 and woven glass fibre that creates a lightweight, mouldable sheet. Its most significant technical credential is passing the demanding UL 2596 Battery Enclosure Thermal Runaway (BETR) test at a thickness of just 2.7 mm. “This standard simulates a direct, sustained internal battery fire, and passing it validates K2500 as a viable, mica-free solution for battery enclosures, potentially reducing weight and simplifying manufacturing,” he says.

Beyond enclosures, Kelvinite addresses the critical risk of cell-to-cell propagation. For this, the portfolio offers specialised barriers. The K2540 cylindrical cell separator is a 2 mm thick K2100-based composite designed to be woven between cylindrical cells, creating a continuous flame-retardant wall. For prismatic cells, which undergo volumetric expansion during charge cycles, the K2520 composite separator introduces a compressible element. It features a K2400 foam core, allowing the pack to accommodate mechanical swelling while maintaining a critical FR barrier, as tested in Highland’s internal prismatic cell thermal runaway simulation.

Complementing these structural solutions, Kelvinite 2105 is an ultra-thin derivative engineered for application in tape form. Capable of being extruded as thin as 0.005 in (0.125 mm) while achieving a UL 94 VTM-0 rating, this halogen-free tape is available with a pressure-sensitive adhesive backing. It provides a solution for automated application in wire harnessing, component insulation, and other areas where flexibility and thinness are paramount.

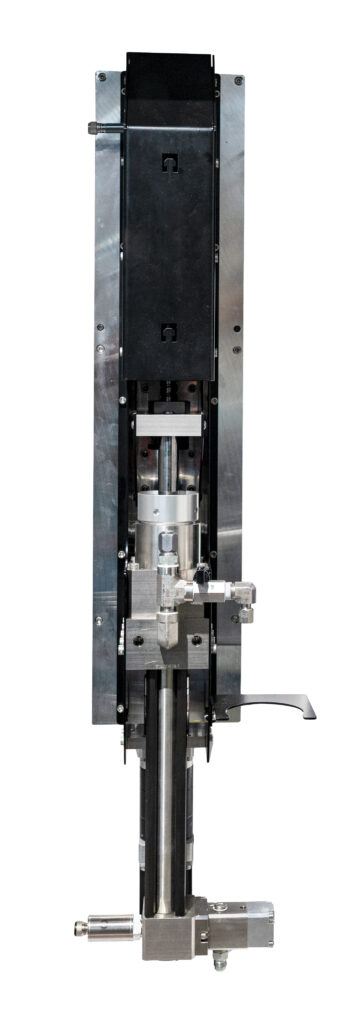

PVA, a specialist in automated dispensing and precision fluid application systems, introduced its new Servo Rod Pump (SRP) developed to address a gap in high-performance metering of a wide range of materials used in battery assembly, including those with abrasive components.

The genesis of the new SRP came from the recognition that existing high-pressure, high-volume metering solutions were often over-engineered and too costly for many applications. “We had designed and have other versions of that were capable of much higher volume, much higher pressures, which were actually too big for a lot of applications such as in a battery. So, we designed the Servo Rod Pump as a smaller, lower-cost version,” explains David Filbert of PVA. This strategic downsize costs around $40,000 – half the price of its predecessor – making advanced metering technology accessible for a wider range of projects.

The SRP is engineered to handle a vast viscosity range, from 10 to 1 million centipoise, with a programmable flow rate of 0.5 to 9 cc/s per component. Its maximum shot size is 100 cc for a single component and 200 cc for a 1:1 ratio mix, operating at pressures up to 1500 psi. This makes it ideal for dispensing abrasive pastes, two-part epoxies, thermal interface materials and potting compounds, which are ubiquitous in EV battery assembly, Filbert emphasises.

The core of the SRP’s robust design is its tungsten carbide metering rod and lip seal system. Unlike piston pumps, the rod never contacts the walls of the metering cylinder. This design is inherently more resistant to wear from abrasive fillers. “A lip seal on a rod is going to wipe away that abrasive material, whereas a piston that has to seal against the inside of the cylinder is going to take more wear.” This results in significantly reduced maintenance requirements and longer service life compared with traditional precision gear or piston pumps, which can be ruined by abrasive materials in minutes.

In operation, a refill valve in the SRP opens and the servo-driven rod retracts while material is pumped into the metering chamber from a source such as a pressure pot, pail pump or drum pump. The valve closes, and the rod then advances, displacing a precise volume of material out to the dispense valve. Closed-loop servo control of the pump allows operators to program not only the flow rate and mix ratio (from 1:1 to 10:1) but also to apply a pre-shot pressure. This is critical in two-part applications with vastly different viscosities, preventing the higher-pressure material from flowing back into the lower-pressure side when the dispense cycle begins.

Since its release and first showing at The Battery Show, the SRP has been rapidly adopted. Its primary applications include applying thermal interface materials to manage heat in battery modules, and potting around individual battery cells with urethane or silicone foams to contain thermal runaway and prevent catastrophic failures.

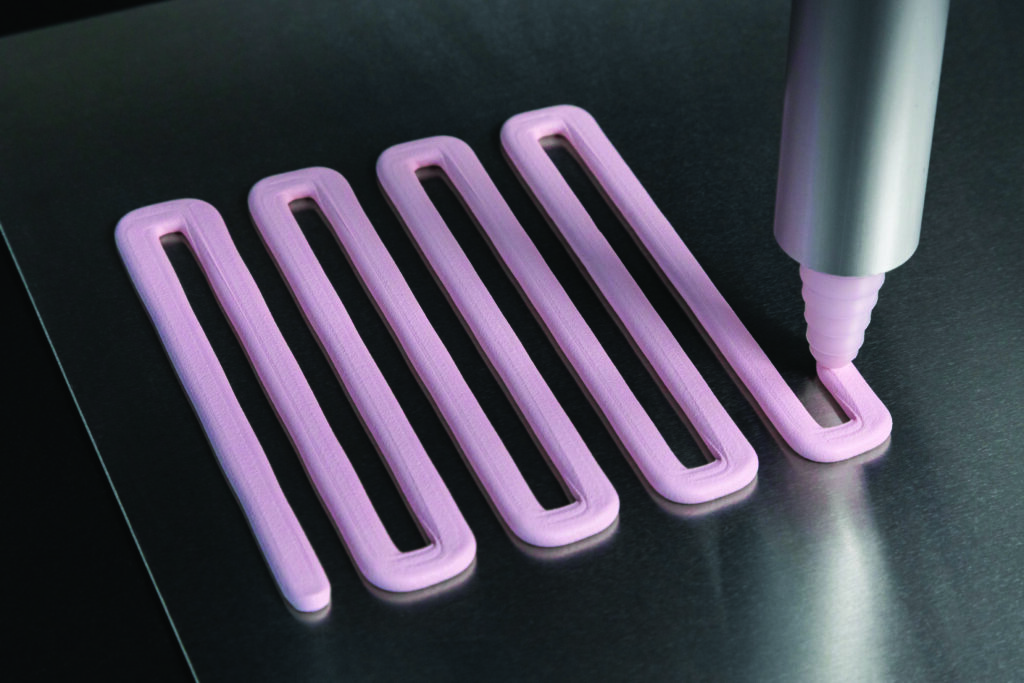

(Image courtesy of Wacker)

Wacker Chemical showcased its new generation of thermally conductive adhesives (TCAs) designed to meet the demands of rapidly evolving EV battery design, such as the shift from cell-to-module to more integrated cell-to-pack and cell-to-chassis architectures. Branded SEMICOSIL®, these new TCAs are multifunctional bonding materials that must also manage heat, withstand extreme environmental stresses, and even allow for repair and recycling.

This new family of TCAs is based on Wacker’s proprietary silane-terminated polyether (STP-E) technology, a hybrid system that bridges the performance gap between traditional material classes. “The polyether backbone gives silicone-like flexibility, while silane end groups cure into a siloxane network that adds mechanical strength and adhesion,” Wacker’s Alejandro Shimazaki explains. This unique structure allows engineers to fine-tune crosslink density, achieving an optimal balance of elasticity and durability essential for dynamic battery packs subjected to constant vibration and thermal cycling.

The new adhesives are engineered to be isocyanate-free, solvent-free and tin-free – for health, safety and environmental reasons. Eliminating isocyanates removes exposure to potent respiratory sensitisers, simplifying compliance with OSHA and REACH regulations. The solvent-free nature means zero VOC emissions, improving indoor air quality and reducing fire risk on the production line. Furthermore, removing tin-based catalysts eradicates highly toxic, bioaccumulative compounds from the curing process, Shimazaki notes.

Thermal ageing and shock are major concerns, often leading to cracking, embrittlement and loss of adhesion in conventional adhesives. The STP-E hybrid is specifically designed to resist these failure modes. “By combining a flexible backbone with a stable siloxane network,” Shimazaki notes, the adhesive can “absorb stress and maintain adhesion even under rapid temperature changes.”

One of the most critical features for modern battery manufacturing and lifecycle management is reworkability. Unlike aggressive epoxies or acrylics that form permanent, brittle bonds within minutes, STP-E adhesives are designed with ‘smart curing’ in mind, meaning that they develop sufficient handling strength for assembly line throughput but can be selectively debonded for service or recycling.

“It does not imply a fully reversible bond,” clarifies Shimazaki, “but the cured STP-E-based TCA can be selectively broken down using the right chemical agent or by applying gentle heat.” This controlled disassembly prevents damage to expensive battery cells and substrates, which is a common problem when removing components bonded with epoxies.

While these TCAs deliver outstanding flexibility, chemical resistance and safety, they do involve calculated trade-offs. Compared with high-performance epoxies, they exhibit lower ultimate tensile strength (1–10 MPa versus 20–40 MPa) and a higher moisture vapour transmission rate. However, as Shimazaki points out, this sacrifice in peak strength and low permeability is a conscious one, made to prioritise “elasticity, durability and safer handling – making them ideal for dynamic joints and environments where flexibility matters more than brute strength.”

The curing process is another area of customisation. Relying on moisture-driven hydrolysis, it can be tailored to manufacturing needs. “You can stick with standard moisture cure at ambient humidity, speed things up with heat or controlled humidity or use dual-cure systems,” Shimazaki explains. This allows formulators to achieve the necessary handling strength and full cure profiles to suit high-volume production lines without necessarily increasing energy consumption.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS