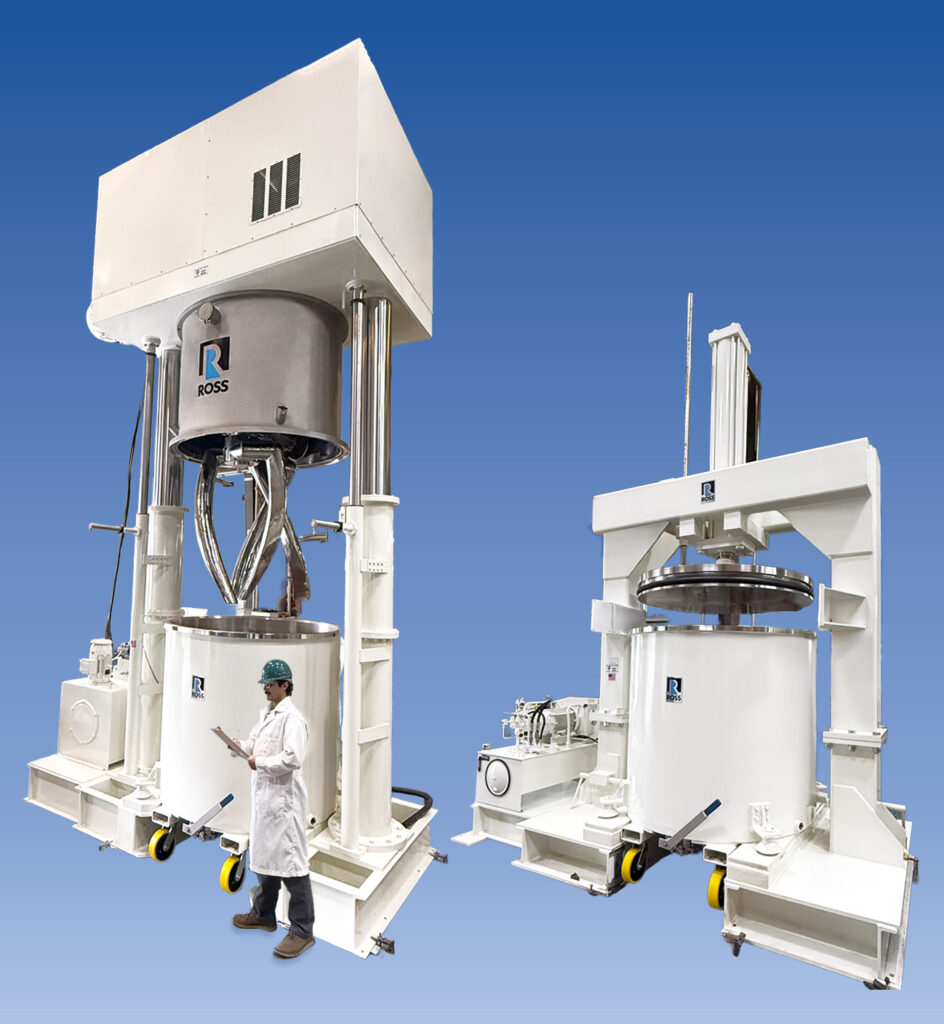

ROSS launches 750-gallon Double Planetary mixer

(Image courtesy of ROSS)

Processing materials that behave more like modelling clay than liquid presents distinct engineering problems. Adhesives, sealants, battery electrode pastes and advanced composite materials can reach viscosities exceeding 5 million centipoise, and at that consistency, achieving uniform dispersion across hundreds of gallons becomes as much about mechanical design as process chemistry.

ROSS recently completed the largest Double Planetary Mixer built in its US manufacturing history. The Model DPM-750 handles up to 750 gallons per batch and incorporates safety systems required for Class I, Division 1, Group D hazardous locations, areas where ignitable concentrations of flammable gases or vapors are present under normal operating conditions. Many high-performance formulations involve solvents or generate volatile compounds during processing, requiring equipment that eliminates ignition sources.

The mixing mechanism relies on planetary motion, where two stirrers rotate on their own axes while orbiting the vessel’s central axis. This pattern ensures material swept to the walls gets continuously pulled back through the batch center, preventing dead zones that plague simpler geometries when working with paste-like compounds. A 150 hp inverter-duty motor provides the torque to drive High Viscosity blades through materials that generate substantial resistance, while the inverter control allows operators to modulate mixing intensity without thermal stress on temperature-sensitive formulations.

Vacuum capability extends the process beyond simple blending. Drawing the vessel down to 29.5 inches of mercury removes entrained air that would compromise material properties in applications where void content must be tightly controlled. In battery electrode manufacturing, even microscopic air pockets can create current distribution problems. The vacuum also improves dispersion of powdered additives by eliminating the cushioning effect that air films create between particles and the liquid phase. The vacuum hood incorporates multiple ports for ingredient charging, exhaust routing and observation without compromising the vessel’s ability to hold vacuum during mixing.

The system uses interchangeable stainless steel Type 304 mix cans with 80-grit polished interiors, a surface finish that balances cleanability against cost. The interchangeable design allows facilities to dedicate specific vessels to different product families, preventing cross-contamination when switching between chemically incompatible formulations.

The dual-post hydraulic lift moves the mix can into position using a 10 hp explosion-proof motor driving twin hydraulic pumps. The can, when loaded with 750 gallons of dense material, must be precisely positioned to ensure the planetary stirrers engage correctly with the vessel’s internal contours. Lock mechanisms with proximity switches prevent stirrer operation unless the can achieves proper alignment, and disable lift motion when the stirrers are rotating.

Emptying 750 gallons of high-viscosity material requires more than gravity. The integrated ram-type discharge system uses a hydraulically actuated platen that descends into the mix can while maintaining 60 psi of pressure through a pressure-compensating circuit. This pushes the batch through a 4-inch flush tank ball valve at the vessel bottom, while the platen’s O-ring seal scrapes the sidewalls clean as it travels downward. Discharge times are measured in minutes, and product recovery rates minimize the economic impact of materials that might cost hundreds or thousands of dollars per gallon.

The 750-gallon capacity represents something of an inflection point in batch processing equipment. Most planetary mixers top out at 300 to 400 gallons because the mechanical forces involved in turning over larger volumes create substantial challenges around bearing loads, shaft deflection and power transmission. Moving to 750 gallons demands careful analysis of how forces distribute through the mixing assembly under various loading conditions, likely reflecting growing demand from industries where batch consolidation offers economic advantages by reducing processing cycles and cumulative downtime during loading, unloading and cleaning operations.

Building equipment for hazardous environments means accepting constraints that wouldn’t apply in general industrial settings. Explosion-proof motors cost substantially more than standard units and require specific mounting practices. Electrical components must be housed in enclosures rated to contain internal explosions and prevent ignition of external atmospheres. These requirements add cost and complexity but remain necessary in facilities processing materials with flash points below ambient temperature or generating combustible dust during handling.

The development of this 750-gallon system reflects the ongoing evolution in mixing technology toward equipment that accommodates both the material science demands of advanced formulations and the operational realities of production-scale manufacturing in regulated environments.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS