Harbinger electric haulage and RV

(All images: Harbinger)

Mid-sized marvel

Harbinger has built a brand-new EV platform for the medium-duty commercial, specialist and RV market. Developed from a clean sheet of paper, its innovative and adaptable design could become a game changer, Will Gray reports

The medium-duty commercial, recreational and speciality vehicle sector contains, arguably, the largest variety of all the categories of vehicles on the road. Tow trucks, work trucks, school buses, shuttle buses, RVs, delivery vehicles, aerial work platforms; these are just a handful of the many functions in which these types of vehicles are engaged on a daily basis – yet very few run on hybrid or electric power.

The relatively niche market for each different application means that vehicles are often developed to suit specific tasks, meaning that the capacity to electrify is limited by economies of scale. It is this very challenge that led to the foundation of Harbinger, just four years ago, with a concept to deliver a ‘three-sizes-fits-all’ electrified chassis capable of meeting the needs of as many different sectors as possible.

“We’ve always had a thesis that these medium-duty vehicles are overwhelmingly good candidates for electrification,” explains Harbinger co-founder and chief technical officer Phil Weicker. “They generally have relatively modest and predictable ranges – in fact, about 75% of medium-duty vehicles in the US travel less than 75 miles per day – and the routes are generally predictable, which helps to manage range anxiety.

“The economics of these vehicles are also very black and white. In the passenger car world, a car is a very emotional purchase for a lot of people whereas most fleet operators are just looking to get their job done in the least expensive way possible. For them, electrification makes a lot of sense because these vehicles drive lots of miles, and operating costs are about half for an EV when compared to a petroleum or diesel-powered vehicle.”

It is common industry practice in this segment for a third-party upfitter to add the job-specific body of the vehicle onto a chassis; that is not special to Harbinger. However, the innovation is in the development of an adaptable chassis design, with three different wheelbase dimensions, a fully integrated electrification solution and battery packaging that can add or reduce capability depending on use case.

“By developing a very standardised chassis to serve as many applications as possible, we are able to increase production volumes and keep costs down,” continues Weicker. “There are some dimensions and package layout considerations that are quite sacred in this industry and by keeping to those standards as much as we can, we can work with existing upfitter ecosystems for all of the different types of vehicles.

“The frame rail spacing and how the body attaches to the chassis is one aspect we’ve tried to keep as standard as possible – and, in fact, in many cases, we’ve been able to take petrol-powered vehicles and swap the bodies straight onto our EV chassis. Making it cost-effective and durable was one of the biggest challenges, as those things are somewhat at odds with each other, but I think we’ve done a good job of making that work.”

Despite the clear appeal for electrification in this sector, the key to success, according to Weicker, is to be able to deliver the electric alternative at a price point that matches that of existing petroleum or diesel vehicles, as opposed to one that costs a premium to employ. It was not until 2021 that the technology was in place to deliver on that a marketable solution, but as soon as that happened, Weicker and his team got to work.

“The battery costs had come down to a level where electric vehicles could be competitive in the marketplace and at the same time, battery longevity was now able to meet the durability demands for this kind of vehicle,” he recalls. “People were also starting to drive electric vehicles in their everyday lives, so we were finally getting to a point where people in the industry were starting to ask why other classes of vehicles were not being electrified.”

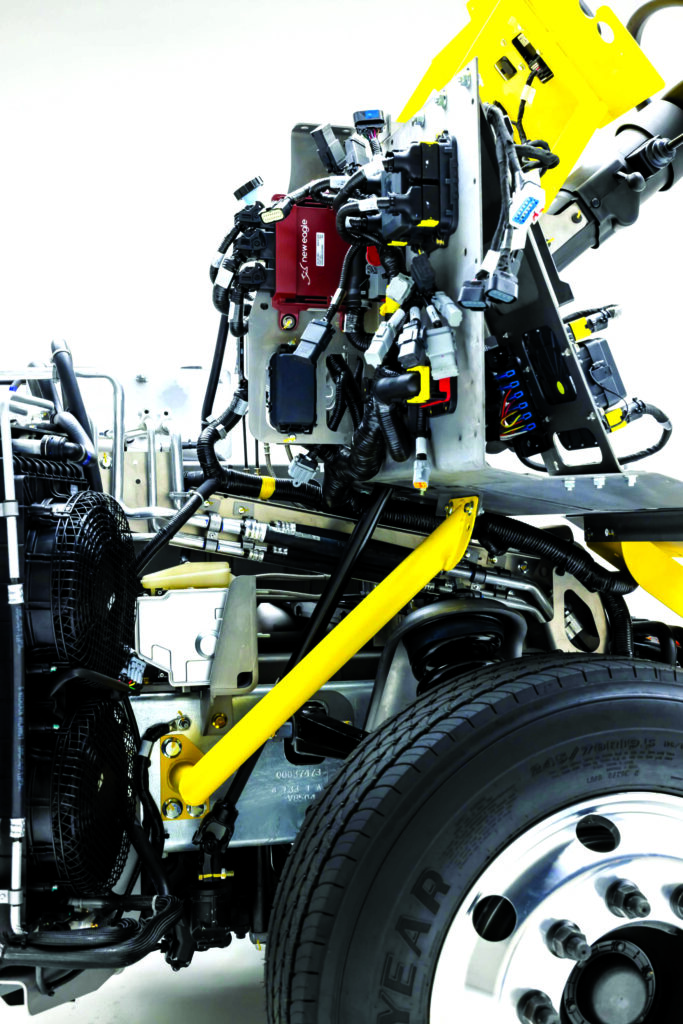

Powertrain design

From the very beginning, Harbinger made a decision to produce as many of the key components as possible in-house – and a significant amount of r&d time went into the development of a bespoke motor to meet the unique needs of the market. This resulted in a unique 12 pole Internal Permanent Magnet (IPM) design with proprietary winding that includes multiple paths and spins to 9800 rpm, with an output speed of 812 rpm. It delivers a peak motor torque of 1550 Nm, translating to 18,100 Nm at the wheel, with a peak power delivery of 330 kW and continuous power of 219 kW.

Those figures were the result of a very precise development process, and Weicker explains: “One of the biggest benefits of electrification is the relatively low capital costs and time associated with developing a new propulsion system. If you look at medium-duty vehicles from ICE providers, market dynamics mean they’re always going to be stuck using an engine that was designed for something else – maybe a gas V8 designed for a muscle car or a diesel engine that probably should have been in a much larger truck – whereas we had the opportunity to develop something that really is the best choice for our application.

“We have seen a lot of other attempts at electrification on medium-duty vehicles, but they are often quite a bit lower power, between 100 and 200 kW. That always comes with compromises, most notably in gradeability. If you want to be able to do last-mile delivery, you need to be able to get to every address, and that means a 32% or better hill climbing capability. That was our target, and the maximum power fell out from the gradeability, payload, handling and acceleration requirements.”

The motor is coupled to a two-stage single-speed gearbox with a ratio of 12.07:1 and integrated, along with the differential, into a single Electric Drive Unit. This measures a compact 753 mm x 635 mm x 418 mm and weighs in at 245 kg, including the motor cooling oil flowing around inside. The space-saving single-component design eliminates many of the interconnections – such as cables, shafts, seals and low-value parts – that would be required to connect individual parts. That reduces cost and weight, takes up less space and delivers an impressive combined efficiency of 94% across the three core systems.

“Simplicity was the focus across this design and the single-speed gearbox is the simplest and easiest solution with the fewest parts, the highest reliability and the lowest cost,” explains Weicker. “The specific gear ratio was the result of a pretty detailed trade study. A higher ratio means your motor can be smaller, lighter and cheaper, but if you go too high, you get a lot of reflected inertia and undesirable driving dynamics and the vehicle feels like it’s in first gear all the time. Trying to find that sweet spot is important.

“When it comes to the torque, we wanted a drivetrain that would deliver power smoothly, without any pulsations or torque ripple from the electric motor, so we also have some special features in there to keep that torque ripple down. We want to transmit that torque as linearly as possible through the gear system, so the design of the gear profiles and how they interact with the stiffness of the drive unit housing are really important.

“Tiny specifications in the manufacturing process of these components, down to the single digits of microns, can make the difference between a really smooth and quiet transmission of power and something that introduces a lot of unwanted torque pulsations or fluctuations. I don’t know that there’s any magic bullet, but certainly hard work by very experienced and competent people has got us to where we are on that.”

Battery and cooling

The battery set-up involves another bespoke in-house design, based upon the use of cylindrical 2170 format lithium-ion NCMA (nickel, cobalt, manganese, aluminium) cells from Panasonic, packaged into a convenient and scalable 35 kWh pack. This is the first high-energy density pack built specifically for medium-duty vehicles and goes against the trend from a lot of other manufacturers to use lithium-ion-phosphate batteries. Weicker explains: “We chose it for two reasons. The first is payload. Our customers often need to carry large and heavy loads and the higher energy density of the NCMA cell considerably reduces the weight and size of the battery required, so we can provide that payload benefit to our customer.

“The 800 Wh/L that Panasonic offers is the best-in-class energy density but, in addition to that, we also wanted a very high-quality battery option that was available domestically within the US. Panasonic is the world’s premier lithium-ion battery cell manufacturer and they are currently transitioning to a US supply as they bring up their Kansas factory over the next months, so it was an ideal choice.” The battery contains 480 cells per module and four modules per pack, creating overall dimensions of 920 mm x 702 mm x 258 mm, a mass of 210 kg and a total volume of 163 L. The energy density of 170 Wh/kg – or 215 Wh/L – leads to a peak output power of 110 kW and continuous output power of 40 kW per pack.

Each of the modules contains an aluminium high-pressure die-cast monolithic cold plate sitting in direct contact with the battery cells to remove heat generated during fast charging and discharging. The architectural design, Weicker says, delivers good cell cycle life and lifetime, but also includes built-in capability to handle the shock, vibration, corrosion and other environmental challenges found in the commercial vehicle market. That in itself required some innovative construction around the cells to ensure protection for a designed vehicle life of 450,000 miles.

“We use vibration isolation – we are the first in the commercial vehicles space to do that – and we also use a large format die casting, which sometimes people refer to as giga casting, to build the enclosure of the battery pack,” explains Weicker. “That provides a very robust structure, not only from a mechanical standpoint but also for corrosion, sealing and other aspects that typically cause challenges for batteries in commercial vehicles.” It results in an IP6k9k protection rating, with capability to withstand temperatures ranging from -40 to +60 C and 10 years or 2000 cycles of use through mechanical, thermal and electrical abuse tests.

The battery is packaged in the frame area of the chassis and the modular approach allows customers to fit multiple packs within that space for different applications. Starting at a minimum of three packs, combined in parallel to deliver the target 330 kWh peak power, there is the option to increase the capacity incrementally in 35 kW packs, up to a maximum of six packs to deliver total capacity of 210 kWh. To optimise safety, the battery sits entirely within the frame, with nothing protruding above or below in any configuration, with the maximum capacity limited by the vehicle configuration, wheelbase and gross vehicle weight.

“The larger battery configurations are only available in the larger vehicle layouts and the packs are all connected electrically in parallel using our high-voltage distribution system,” says Weicker. “When we configure a vehicle with fewer packs, we remove them from the rearmost position to provide more payload in the lighter configurations. To date, though, most vehicles have been configured with larger batteries than we would have expected – but as customers get more familiar with our vehicles and understand how they operate on their routes, I think people will start to request smaller battery capacities.”

Given the large battery capacity at the upper end, Harbinger opted for an 800 V system to minimise charging times and reduce the size of the cable and charging handle required. An advanced liquid-cooling system enables rapid charging speeds via two standard integrated charging options – AC and DC – delivering a continuous C-rate of around 1C and a peak of around 2.5C. This results in a continuous fast charge of around one hour for the highest capacity battery.

“We use a traditional CCCV [constant current, constant voltage]-type charging approach and with the multiple parallel packs, we also need to give a little bit of time for packs to equalise,” says Weicker. “Like everybody, we have to strike the balance between how high we want to go in state of charge and how much lifetime we want to provide. So, we typically won’t recommend for most customers to charge all the way, but we can provide a very substantial fraction of the state of charge for customers to use.”

Regenerative braking adds into the mix, operating exclusively on the rear drive wheels, as is the typical approach in other electrified medium- and heavy-duty trucking solutions. This typically achieves between 0.2G and 0.3G of deceleration, which is enough to capture the energy from most typical deceleration events. It is combined with traditional braking in the form of hydraulic 4-wheel vented disks with dual piston callipers, and Weicker proudly states: “We’re the first vehicle in our weight class to offer fully blended braking in a way that’s completely seamless, so the driver experience is much like you would have in a modern passenger car EV.”

Harbinger has integrated many layers of safety features into the battery design, from the way in which multiple cells are integrated together within the module, to the method of packing and the manner in which the vehicle integration is designed. It has also been put through intense mechanical, thermal and environmental, electrical and fire safety testing. Harbinger developed road load profiles to ensure at least 10 years of mechanical durability, meeting industry standard SAE J2380, and the pack is also validated to withstand 18 consecutive 25G shock loads – which is typical of a repairable crash – with no impact to function or safety. It has also met UN ECE R100 thermal cycle/thermal shock requirements with no impacts to performance or serviceability, and the battery cooling components are validated to be leak-free through the entire life of the battery pack.

The advanced Battery Management System (BMS) monitors and balances all the individual cell voltages and temperatures at all times and has been validated per UN ECE R100 to safely respond during overcharge, over-discharge, over-temperature and over-current conditions. Through extensive testing – including hundreds of cell-level evaluations, dozens of multi-cell cluster trials and 30 full battery pack assessments – it has validated capability to passively resist thermal runaway – an essential requirement to deliver a safe, durable and reliable lithium-ion battery system – while external fire resistance testing has shown that there are no safety concerns through flame exposure over a duration of 130 seconds.

The system is also validated to ensure continuous and proper isolation of the high-voltage system from the rest of the vehicle and incorporates multi-level short-circuit protection at the cell, pack and system level, validated to UN ECE R100 and UN 38.3 standards through cell, module and pack-level fusing and switching. Proprietary reasons prevent Weicker from providing functionality details for this, but he does explain how the intelligent construction and fabrication of the battery pack has achieved ingress protection against physical impacts and environmental factors.

“Battery enclosures in passenger cars are typically made of thin sheet metal, welded or glued together from multiple pieces, and although that may be appropriate when targeting 150,000 miles of life, it is not good for the environment in which a commercial vehicle operates,” he explains. “To be more robust, we make the battery enclosure out of as few pieces as possible, with a very tight sealing interface and a material inherently resistant to corrosion, allowing us to achieve very good performance on ingress, dust and corrosion.”

Onboard cooling is delivered through oil for the motor – giving maximum power density – and liquid for the batteries and ancillaries. In another sector-first innovation, Harbinger has brought in an integrated heat pump system, which includes design-flexible front-end dual radiators, to organise thermal management between the different onboard systems. “Every vehicle has different sources of heat generation and consumption,” he explains. “There is heat generated in the battery, drivetrain and power electronics, and heat consumed for heating the cabin and warming up the battery or other vehicle components when necessary.

“The default solution used by a lot of manufacturers is to deal with each one separately, with a cooling system to extract the heat from the heat-generating components and heating components to heat the things that need to be heated. That’s a simple way of doing it, but it requires a lot of different heaters on separate cooling loops and it’s very inefficient. You are using battery energy that could be used for vehicle propulsion to generate heat, and you have a lot of waste heat that’s not being used.”

Instead, Harbinger’s heat pump system utilises a six-way coolant valve and high-, medium- and low-temperature cooling loops, with modes that allow the operator to select how and when to move heat from heat-generating components to heat-consuming components in a very efficient way. “It’s a simple and neat solution to get that heat for free and not have to use up our battery energy,” he concludes. The system achieves a high coefficient of performance heating – which improves vehicle range – and it uses electric resistive heaters to deliver high heating power that maximises performance in low temperatures. It is one of the few parts that requires occasional attention and so the unit is conveniently side-mounted, allowing for quick removal and servicing to minimise vehicle downtime.

The heat pump system delivers a total capability of 30 kW, with 10 kW available for battery cooling, 8 kW for battery heating and cabin heating and 7 kW for cabin cooling. With a coefficient of performance greater than one, it delivers better heating performance than would be achieved with a traditional resistive heater, and Weicker continues: “All these things are important, especially if you look at some of our use cases. For example, a vehicle in a cold urban environment might use more energy heating the battery and occupant than it does driving on a very short route. People often talk about concerns about EV range degrading in low temperatures, so we wanted to minimise that as much as possible.”

Chassis innovation

It is a rare opportunity to be able to start a new vehicle design with a clean sheet of paper. Identifying priorities can be daunting, but from the get-go, Weicker had a crystal-clear focus. The first lines on the paper were the dimensional restrictions that are required to meet the three key chassis sizes on the market, resulting in the definition of three wheelbase options of 158, 178 and 208 in. These options are all delivered through a scalable stripped chassis capable of supporting all the medium-duty body types available, with four different Gross Vehicle Weight Ratings (GVWR) of 8, 9.75, 11 and 13 tonnes for maximum flexibility, achieved through a configurable Front Gross Axle Weight Rating of 3.265 to 4.082 tonnes and a Rear Gross Axle Weight Rating of between 4.989 and 7.937 tonnes.

From that baseline, the development of the chassis design was all about exploring all the avenues offered by that clean sheet of paper to improve on the existing market offering. “I would say that a lot of medium-duty vehicles are an afterthought for many companies,” offers Weicker. “They’re either coming at it from the passenger and light-duty truck segment or from the heavy Class 8 segment and see this as an opportunity to repurpose some components, so in many cases you get a pretty compromised product out of that.

“Most traditional medium-duty vehicle suspension and chassis layouts are between 40 to 80 years old – we see things like solid front axles and drag link steering, which haven’t been used in a passenger car since the 1940s. I don’t think anybody has ever made driver comfort or ride quality a priority before, so having that focus has given us the opportunity to make a lot of good improvements.”

The Harbinger chassis has the first ever application of double wishbone (or double A-arm) suspension in its weight class, combined with coil-over dampers and an anti-roll bar in a creative suspension module that is attached at the two front corners. As well as improving handling, the solution comes with the added benefit of much improved battery packaging.

Although this type of suspension is relatively common in passenger cars, and even in light trucks, the medium-duty sector’s legacy design approach has so far prevented it from making an appearance on a much larger scale.

At the rear of the vehicle, the team has opted for another innovative approach in the form of a De Dion axle – a solution that first saw the light of day on French sports cars at the turn of the last century but had long fallen out of favour. The design was all but obsolete in the industry until Harbinger and a handful – if that – of other companies identified the potential for it to deliver huge benefits in electrically powered trucks. “It’s been in the back pages of automotive history for probably about a hundred years but for a number of unusual reasons we thought that it was a good choice,” begins Weicker.

“The electric motor, which can be a fairly fragile component, is typically mounted using a live axle and it is bolted where the differential would be. That is one of the most difficult environments in the vehicle. The De Dion solution allows us to separate it and mount it to the chassis on the right side and it also enables us to use leaf springs and an anti-roll bar – which is the right choice for a vehicle in this weight class – then connect the wheels using a rigid forged axle, which is a pretty compact and lightweight component. Typically, this has been done with a steel tube but we were able to update that using an advanced forged component that has delivered an excellent overall integration.”

Harbinger put a lot of work into reducing the vehicle’s NVH (noise, vibration and harshness) by optimising the gearset and motor and by using mounting techniques to reduce transmission. The suspension, powertrain and battery packs are all mounted within an industry-standard medium-duty 80 ksi structural steel frame. This is manufactured using stamped, rolled and forged components and finished with a hot dip galvanisation process. There is no traditional subframe, as would be found in a light-duty vehicle, but there is a significant amount of separation using isolation components.

Weicker explains: “We brought a passenger car level of analysis, refinement and testing to our NVH process. No one wants noisy vehicles anymore and as we see more electric vehicles in regular use cases, we become more and more sensitive to vehicle noise. NVH is a big factor in work trucks, delivery trucks and other types of large vehicles, and on a vehicle as long as ours, the frame actually has quite a bit of movement. So, we have to isolate those components – particularly in the case of the drive unit – not only for noise but also to manage twist and deflection.”

Manoeuvrability was also a very important factor in the chassis design because commercial vehicles are often required to operate in tight spaces while RV drivers need to be able to cope with tight turns when driving through winding mountain passes or country lanes. To meet this requirement, the chassis includes electric power-assisted steering with dual packs and has been designed with a 50-degree wheel cut, which is one of the tightest on the market.

While making the wheels turn at a greater angle may sound simple, Weicker can attest that it is far more challenging that it first appears. “A lot of components had to be customised for that,” he explains. “We had to fit the brakes inside the wheels, and there were challenges with other individual components and the use of high-strength materials. In our weight class, ball joints and other articulating suspension components are not that common, so a lot of work went into making what sounds like a pretty simple design a practical reality.”

Driving performance forward

Harbinger’s original aim was to deliver a vehicle with all the responsiveness of a modern passenger EV and the attention to detail in its development has achieved that, with performance figures that compare extremely favourably with the current class-leading petrol and diesel machines on the market, whatever body type is attached. “If you look at acceleration, torque and most of all drivability, a lot of the vehicles in our weight class typically feel pretty sluggish,” says Weicker. “In a large part, that is due to the fact the powertrain is adapted from other vehicles. Our performance is on another level to that.”

So too is its durability, simply because of the benefits of an electric powertrain. Weicker continues: “On an ICE, you have a lot of moving parts and that means there’s a lot of wear, friction and entropy. You just don’t have that in an electric vehicle and I think that people are also now starting to realise that batteries are quite a bit more durable than they expected them to be. If we look at everything else in the vehicle, all of that translates into things lasting longer.”

The vehicle’s overall range is quoted as between 175 and 210 miles, depending on the battery configuration. That is well beyond the 75-mile typical daily travel figure for the sector that Harbinger has estimated is required. Weicker says that now the vehicles are out on the roads, customer validation has proven those quoted numbers hold up in the real world and he adds: “There is, of course, range variation, depending on many different factors but, in general, those are numbers that we can stand behind.”

That range can be increased further through the company’s hybrid solution – which has already proven to be an appropriate solution for the current RV market. Unlike a typical ICE-first hybrid solution, this design works on the principle of range extension and Weicker adds: “We start from an electric platform with a fairly significant battery capacity and add the range extender on top of that. There’s no mechanical connection between the engine and the wheels – no transmission, no gears to shift and no power split device – so the engine is simply there to provide additional electrical power through a generator to the battery.”

The vehicle is fitted with a high-accuracy Inertial Measurement Unit (IMU) and wheel speed sensors, enabling Harbinger to include the full suite of advanced braking and stability features that is typically found only on passenger cars and light-duty vehicles. That includes traction control, electronic stability control, anti-lock braking and roll mitigation, together with visual driver assistance features such as front and rear virtual bumpers, dynamic trajectory and overhead cameras – none of which have ever been seen before in this market.

There is currently only a limited number of control modes – fewer than seen in passenger cars – but that is simply because the company is trying to make things simple for the driver by making the vehicle smarter and enabling it to do as many tasks as possible seamlessly. That ensures drivers can focus on the job at hand, rather than having to switch between different performance modes. However, the company does offer over-the-air updates and plans to add new features in the future through continued upgradability.

In just over four years, the company has gone from a good idea to a full-fledged vehicle manufacturer – a rapid rise made possible only by the nimble and dynamic management structure of a true startup. The vehicles, says Weicker, are already “essentially in the same price range” as the petrol-powered vehicles in the sector and will become increasingly price-competitive as the components become more cost-effective, technology improves and production volumes increase.

That will define the level of Harbinger’s success, and Weicker concludes: “The medium-duty fleet commercial segment has really been something that has been seen as a really good use case for electrification for a long time, but the market needed to see something that was cost-effective. Hitting those price targets is the thing that makes a difference for our customers.

“Ultimately, we wanted to be a vertically integrated company – at least on our key components – and being able to achieve that is certainly something we’re tremendously proud of – but I think most of all, we’re proud of the depth to which we’ve accomplished things and the fact that we have brought so much technology into this space in such a short period of time and with such a small and focused team.”

The Thor hybrid RV project

One of the first strategic partnerships Harbinger has entered into with its hybrid/electric medium-duty platform is with leading RV manufacturer THOR Industries. Together they have created the world’s first hybrid Class A motorhome – and this is how they did it.

As environmental regulations tighten, there is growing demand for lower-emission vehicles in the RV space – a sector which is known for large, heavy and historically inefficient vehicles. THOR Industries president and CEO Bob Martin says that electrification will “play a central role in the future of RVing” and to meet this requirement, the company struck up a strategic partnership with Harbinger in November 2022 to create a high-performance hybrid/electric Class A motorhome, as part of THOR’s eMobility innovation strategy.

Even though studies show that the daily journeys of many RV drivers would not require the maximum range offered by Harbinger’s biggest battery solution, the pure battery electric platform would clearly face range anxiety challenges when it comes to long-distance motoring – so at this stage, the two companies opted to develop the THOR Test Vehicle project upon the hybrid version of the Harbinger platform.

After selecting a suitable chassis wheelbase for the unique layout requirements of the RV design, four modular battery packs were combined to deliver a total of 140 kWh. That delivers a range of 105 miles on battery alone, with the petrol-powered range extender increasing it to an estimated road range of up to 450 miles, while still qualifying as a Near-Zero Emission Vehicle (NZEV) under the Advanced Clean Truck legislation, adopted by the California Air Resources Board (CARB).

Harbinger’s electric performance delivers ample power and torque for mountain driving – with THOR stating it offers up to twice the torque of a diesel engine – and road tests have demonstrated the suspension and electric drivetrain combine to deliver a quieter ride with reduced sway and increased control and safety. Once on site, the integrated heat management system – which manages the battery, range extender and an integrated solar rooftop – extends potential time off-grid and simplifies energy management. This enables it to support living amenities such as air conditioning, cooking and lighting while also allowing for onboard charging for devices ranging from e-bikes to electric power tools. Then, when back home, the vehicle also has the capability to offload power and serve as an emergency energy backup if required, to keep essential systems running.

Harbinger delivered its first customer hybrid-electric chassis to THOR’s Innovation Lab in Elkhart, Indiana (USA) in April 2024, ready for upfitting and design work to suit the specific RV application. A year and a half later, the finished vehicle was launched into the market as the Embark, manufactured by Entegra Coach, with full production due to commence in 2026. The vehicle will initially be available for rental in the US, enabling the team to use consumer feedback from the fleet to make continuous product improvements throughout 2026.

“Thor is the world’s premier manufacturer of recreational vehicles and this is their first product on our chassis,” says Harbinger CEO Phil Weicker. “We think that together we can deliver a complete game changer in driving experience and in the overall user experience, and how we provide power for house loads and comfort in a highly integrated product. We’re looking forward to building a wide variety of very exciting products with THOR – and we can imagine doing other projects with body manufacturers in different segments too.”

Vehicle details

Performance

Power: 330 kW Peak / 219 kW continuous

Peak torque: 1550 Nm (at motor); 18,100 Nm (at wheel)

Range: 105 – 210 miles

(depending on configuration)

Charging time: 1 hr

Specifications

Wheelbase options: 158, 178 or 208 in

GVWR: 16,000 lbs, 19,500 lbs,

22,000 lbs or 26,000 lbs

Motors: 1 x permanent magnet

AC motor

Batteries: NCMA, 35 kWh packs, scalable to 210 kWh (3–6 per vehicle)

Battery mass / power: 210 kg; 110 kW (peak) or 40 kW (continuous)

Gear ratio: 12.07:1

Charging: J1772 (L1/L2) and CCS1 (L3) compliant

Front suspension: Double A-arm with coil-over damper and anti-roll bar

Rear suspension: De Dion beam with leaf springs and anti-roll bar

Brakes: Hydraulic, 4-wheel vented disc with dual piston callipers; ESC, TSC, ABS and regen

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS