Scansonic’s FCW laser optics drive breakthrough in EV battery pack welding

(Image courtesy of Bergmann & Steffen)

Scansonic’s laser technology is playing a central role in the latest generation of battery manufacturing systems, helping automakers overcome one of the biggest challenges in mass-producing electric vehicles: welding thousands of individual cells quickly, reliably, and with absolute precision. German welding and joining specialist Bergmann & Steffen has developed a system specifically for this task, integrating Scansonic’s compact FCW scanner optics as the core element for high-speed battery assembly.

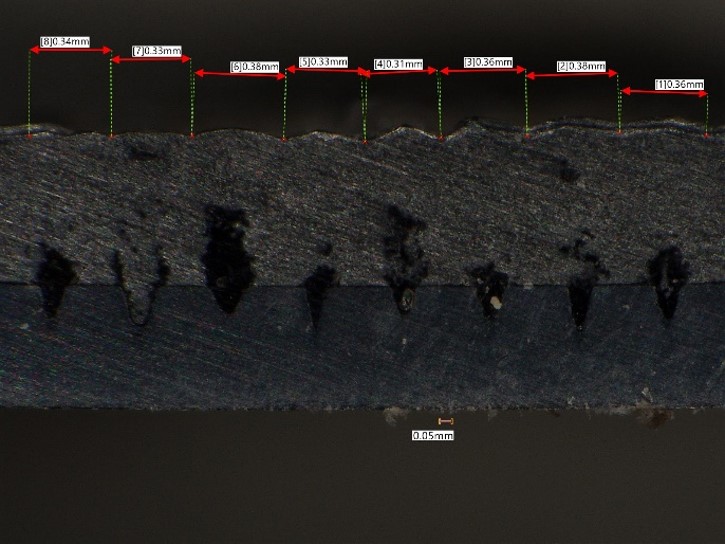

As cell formats grow in scale and battery packs demand ever-larger serial connections, the reliability of each weld becomes critical. In tests with one leading carmaker, 960 cells per pack must be joined using aluminum connectors welded to aluminum anode surfaces and nickel-plated steel cathode contacts known as Hilumin. This dissimilar metal welding presents considerable challenges, as Hilumin combines corrosion resistance and low contact resistance but requires precise laser process control to avoid defects. Any inconsistency in the process risks invalidating a complete pack. High production volumes add to the pressure, not only requiring weld accuracy within tight positional tolerances but also cycle times fast enough for series manufacturing.

(Image courtesy of Scansonic)

Scansonic’s contribution has been to enable dynamic, on-the-fly laser welding that maintains focus and beam quality across a wide scanning field. The FCW optics were designed from the ground up for high-performance industrial use, with a directly driven collimation system that adjusts focus in real time to scanner movement. This ensures stability under thermal load, avoiding the drift problems associated with conventional optics. With magnification ranging between 2.9 and 6 times, and compatibility with both single- and multi-mode lasers up to 6 kW, the FCW system can be tailored to the joint geometry, the cell materials, and the required penetration depth.

(Image courtesy of Bergmann & Steffen)

Bergmann & Steffen built its patent-pending Scanwalker system around these capabilities. Dual clamping units secure the connectors in a walking motion along the pack, while the Scansonic optics, mounted on a separate linear axis, execute welds at speeds fast enough to handle four connections per second. An integrated camera communicates position data to the scanner within microseconds, synchronizing the clamping, drive, and laser control systems seamlessly. The result is a flexible, high-throughput production process that ensures consistent quality across hundreds of welds.

According to Bergmann & Steffen, only Scansonic’s welding optics provided the process reliability and performance necessary to make the system practical for mass production. The companies collaborated closely during development, with Scansonic incorporating EV-specific welding strategies into the optics before they were even commercially released. This brought advanced functionality such as path-controlled mirror motion, precise laser spot control, and scalable scan fields of up to 400 by 310 millimetres into an integrated solution for battery pack assembly.

The pilot system, which began operation in 2024, has validated the viability of series manufacturing using Scansonic optics at its heart. For automakers, the technology offers a route to scaling production efficiently while meeting demanding standards of safety and quality. For Scansonic, it confirms the FCW system as a key enabler of next-generation battery welding, developed directly in response to the manufacturing challenges of electromobility.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS