New electrolyte technology targets four-minute EV charging and sub-zero performance

The persistent challenges of slow charging speeds and cold-weather capacity loss in lithium-ion batteries have prompted 24M Technologies to develop what the company claims is a breakthrough electrolyte formulation. The new Eternalyte technology addresses two critical barriers to widespread EV adoption: charging infrastructure limitations and performance degradation in extreme temperatures.

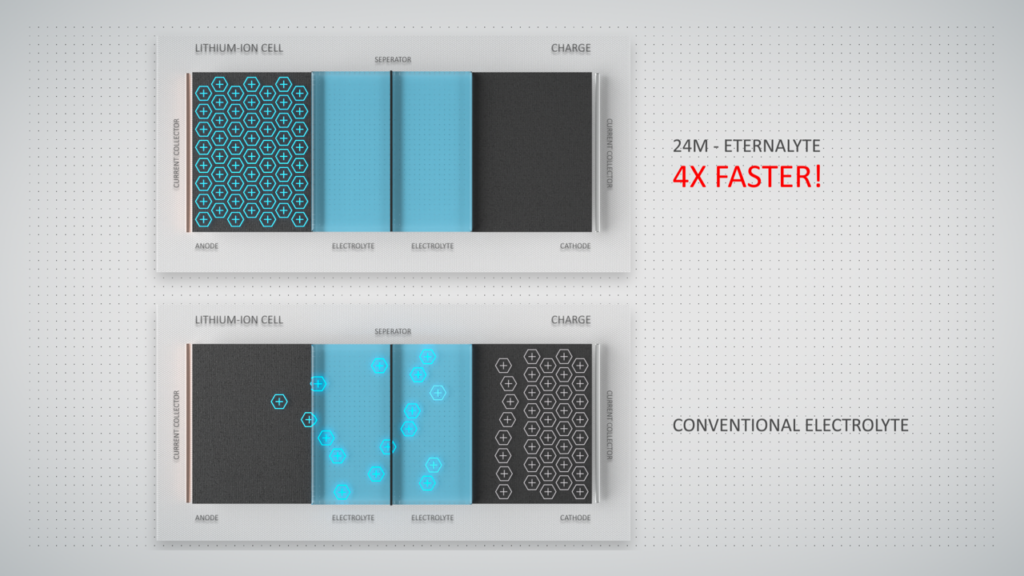

At the core of Eternalyte’s performance improvement is a significant increase in ionic conductivity, the rate at which ions flow between the battery’s anode and cathode. According to 24M Technologies, the new electrolyte achieves up to three times the ionic conductivity of conventional formulations, directly translating to enhanced charge acceptance rates.

This improved ionic transport enables charge rates four times higher than standard electrolytes, with the company demonstrating the ability to add over 300 kilometers of driving range in under four minutes when charging from 15% to 80% state of charge. Notably, 24M claims this performance can be achieved without requiring megawatt-class charging infrastructure, potentially simplifying deployment for charging network operators.

Low-temperature performance has remained one of the most significant technical hurdles for EV adoption in colder climates. Conventional lithium-ion cells typically suffer approximately 25% capacity loss at 0°C, with performance degrading further at sub-zero temperatures to the point of near-inoperability. 24M’s testing indicates that Eternalyte maintains essentially full capacity at 0°C and retains more than 80% of its capacity at -40°C. This performance profile, if validated in real-world applications, could substantially expand the operational envelope for EVs in cold climates where winter performance has been a significant adoption barrier.

The electrolyte technology was initially developed for lithium metal battery architectures but demonstrates compatibility with silicon and graphite anode chemistries currently used in production vehicles. This backward compatibility could ease adoption for manufacturers seeking to upgrade existing cell designs without complete platform overhauls.

“24M’s Eternalyte electrolyte breakthrough solves some of the biggest challenges of lithium-ion batteries today,” said Naoki Ota, President and CEO at 24M Technologies. “Rapid charge, superior low-temperature performance and great cycle life with lithium-metal and other high energy density chemistries, Eternalyte provides outstanding performance for applications ranging from EVs to consumer products.”

When paired with the company’s Impervio separator technology, 24M suggests the complete system can deliver enhanced safety characteristics alongside the performance improvements, a critical consideration for automotive qualification processes.

24M Technologies reports that Eternalyte is designed for integration with existing cell manufacturing lines, potentially reducing barriers to adoption for battery manufacturers. The company projects that the technology roadmap supports development of lithium metal batteries with driving ranges up to 1,600 kilometers and operational lifespans matching vehicle service expectations.

The technology’s ability to enable rapid charging without requiring infrastructure upgrades could prove particularly significant for OEMs and charging network operators, as it potentially reduces the capital investment needed to deliver competitive charging experiences.

As the EV industry continues to address range anxiety and charging infrastructure concerns, electrolyte innovations like Eternalyte represent one pathway toward batteries that more closely match the convenience expectations set by conventional vehicles. The technology’s commercial viability will ultimately depend on manufacturing scalability, cost considerations, and real-world validation of the performance claims.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS