Advanced PEEK materials enable high-voltage EV motor performance

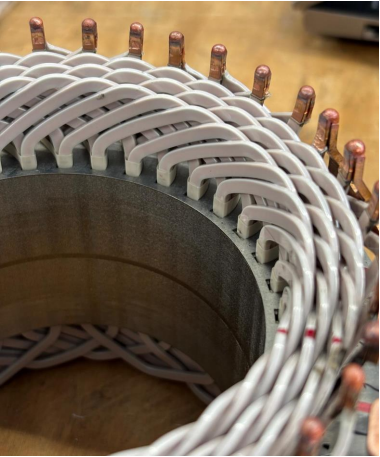

(Image courtesy of Mavel)

Syensqo’s Ajedium™ and KetaSpire® PEEK solutions optimize slot fill factor and thermal management in premium sports car application

Mavel Powertrain has integrated Syensqo’s advanced polyetheretherketone (PEEK) materials into its latest high-voltage electric motor architecture, targeting applications exceeding 800V nominal system voltage. The implementation leverages Ajedium™ PEEK slot liners and slot wedges alongside KetaSpire® PEEK magnet wire insulation to address critical design challenges in high-performance traction motors.

Material Selection and Performance Characteristics

The motor design utilizes a combination of specialized PEEK formulations to maximize slot fill factor while maintaining dielectric integrity at elevated voltages. Ajedium™ PEEK slot liners provide enhanced dimensional stability and reduced thermal expansion coefficients compared to traditional polyimide films, enabling tighter manufacturing tolerances and improved electromagnetic performance.

The monolayer KetaSpire® PEEK magnet wire insulation system offers several advantages over conventional enamel-based solutions:

- Reduced insulation thickness, enabling increased copper cross-sectional area within fixed slot geometry

- Enhanced thermal conductivity for improved heat dissipation from winding to stator core

- Superior dielectric strength, maintaining breakdown voltage performance above 800V system requirements

- Chemical resistance, withstanding automotive coolant exposure and thermal cycling

Electromagnetic and Thermal Performance Benefits

The reduced insulation thickness achieved through PEEK implementation directly impacts motor power density metrics. By increasing the copper fill factor within existing slot constraints, engineers can achieve higher current density while maintaining acceptable I²R losses. This approach is particularly critical in high-performance applications where peak power requirements exceed 300 kW.

Thermal management improvements stem from PEEK’s superior heat transfer characteristics compared to air gaps typically found with thicker insulation systems. The enhanced thermal path from conductor to lamination stack reduces hot spot formation and enables higher continuous power ratings.

High-Voltage Design Considerations

Operating voltages above 800V present unique engineering challenges for motor insulation systems. The PEEK material selection addresses partial discharge inception voltage requirements while maintaining long-term reliability under automotive environmental conditions. Corona resistance and surface tracking properties of the selected PEEK grades exceed automotive qualification standards for high-voltage applications.

“Advanced materials are fundamental to the development of next-generation electric powertrains,” said Luca Favre, Head of Motor Development at Mavel Powertrain, emphasizing the critical role of material selection in traction motor design.

Complementary Material Solutions

Beyond the primary insulation system, Syensqo’s portfolio includes additional materials optimized for e-motor applications:

- Amodel® PPA: High-temperature polyphthalamide for busbar assemblies and high-current connectors

- Ryton® PPS: Polyphenylene sulfide offering excellent dimensional stability for precision components

- Xencor™ PPA LFT: Long fiber thermoplastic composite for structural slot wedge applications requiring enhanced mechanical properties

Industry Impact and Future Applications

The successful integration of advanced PEEK materials in premium automotive applications demonstrates the viability of high-voltage motor architectures for next-generation BEV, PHEV, and series hybrid powertrains. As system voltages continue to increase toward 1000V and beyond, material innovations in insulation technology will become increasingly critical for achieving target power density and efficiency metrics.

“This collaboration advances the performance and reliability of electric and hybrid powertrains,” said Brian Baleno, Director of Global Business Development and Program Management at Syensqo, highlighting the broader implications for the industry.

The collaboration between Mavel Powertrain and Syensqo represents a significant advancement in high-voltage motor technology, with potential applications extending beyond premium sports cars to commercial vehicle and industrial motor markets requiring similar performance characteristics.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS