Compact active suspension power for EVs by Hongfa and Vicor

(Image courtesy of Hongfa)

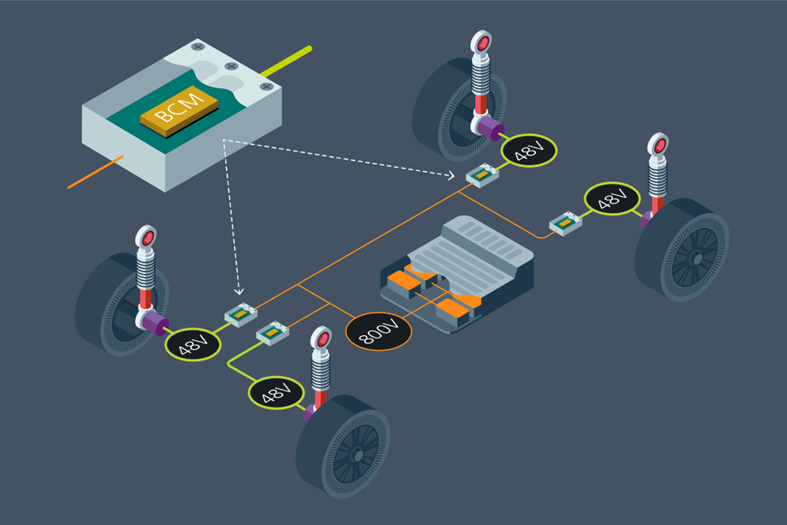

Hongfa has introduced what it claims is the smallest and highest performing active suspension power system yet developed for automotive applications, targeting the migration of this long-standing luxury feature into the mid-range EV segment. The system is built around Vicor’s BCM6135 fixed-ratio DC-DC bus converter modules, which enable direct conversion from the vehicle’s 800V traction battery down to a 48V power delivery network. This approach addresses the traditional challenges of active suspension—namely, the need to balance high transient performance and efficiency with strict constraints on system size and weight.

Previous attempts at active suspension, dating back to the 1970s, were hampered by the limitations of 12V battery systems, which necessitated large, heavy motors and resulted in bulky, inefficient solutions. Even recent designs using conventional DC-DC converters have struggled to combine compactness with the fast transient response required to support regenerative operation and energy recovery.

Hongfa’s new system leverages the high power density and bidirectional capability of the BCM6135 modules. Two modules are paralleled to form a compact 5kW power supply for each actuator, capable of handling peak loads up to 6kW in both directions. The converter’s fast transient response—up to 8 million amps per second—enables the system to rapidly switch between motoring and regeneration, supporting advanced suspension control strategies and efficient energy recuperation.

The packaging of the power supply is notably compact, with a housing volume of less than 1.8 litres and a weight of just 2.6kg. Liquid cooling allows the system to deliver up to 100A of current across an input range of 420V to 920V, with a peak efficiency of 97.3%. This represents a significant reduction in both size and mass compared to previous solutions, while also simplifying thermal management thanks to the planar construction of the Vicor modules.

By moving to a 48V zonal architecture and eliminating the need for a separate auxiliary battery, Hongfa’s design reduces cabling complexity and overall vehicle mass. The modular nature of the power system also allows for scalability across different vehicle platforms. According to Peter Li, Director of R&D at Hongfa, the adoption of Vicor’s modules not only met the demanding performance requirements but also accelerated the development process and simplified the system architecture.

This collaboration between Hongfa and Vicor demonstrates how advances in high-density power modules and 48V power delivery are enabling new levels of innovation in automotive electrification. The result is a compact, efficient, and responsive active suspension system that brings a premium driving experience to a broader range of electric vehicles.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS