Parker launches CoolTherm TC850 for EV battery integration

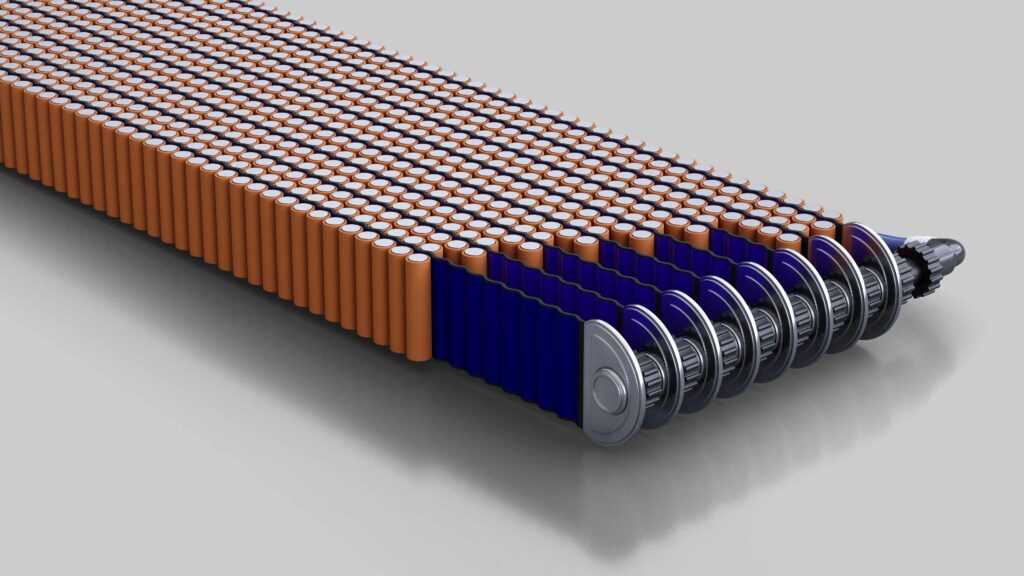

Parker Hannifin has expanded its CoolTherm materials portfolio with the introduction of CoolTherm TC850, a thermally conductive structural adhesive engineered for electric vehicle battery pack applications. The new material addresses critical requirements in battery module assembly, including efficient thermal management, structural bonding, and process optimization.

Technical Overview

CoolTherm TC850 is formulated to provide high thermal conductivity and robust mechanical adhesion, supporting the direct bonding of battery cells to cooling plates or chassis structures. This approach enables higher energy density and compact battery pack designs, which are increasingly prioritized by original equipment manufacturers in the electric vehicle sector.

The adhesive cures at ambient temperature, facilitating integration into automated assembly lines and reducing cycle times compared to traditional thermal management and bonding solutions. Its rheological profile allows for high-speed dispensing, supporting mass production environments.

Performance Characteristics

- Mechanical Properties: High elongation and impact resistance improve the durability of bonded joints, accommodating differential thermal expansion between dissimilar materials.

- Substrate Compatibility: The adhesive demonstrates strong adhesion to common battery pack substrates, including aluminum, copper, steel, and engineered plastics.

- Thermal Management: Optimized thermal conductivity enhances heat dissipation from active battery cells, supporting thermal runaway mitigation and overall pack safety.

- Electrical Isolation: The material provides redundant dielectric protection, contributing to electrical isolation within multi-cell modules.

- EHS Considerations: The improved environmental health and safety profile reduces handling risks during manufacturing.

By minimizing the reliance on mechanical fasteners, CoolTherm TC850 supports weight reduction and simplifies battery pack architecture, contributing to higher gravimetric and volumetric energy densities.

Application and Integration

CoolTherm TC850 is compatible with standard automated dispensing equipment, enabling precise application and repeatable bond lines. Its room-temperature cure profile eliminates the need for thermal post-processing, further streamlining production workflows.

The adhesive is part of Parker’s broader strategy to deliver multifunctional materials that address the evolving challenges of electric vehicle battery integration. The company’s global technical support network provides design and process optimization guidance for OEMs and battery manufacturers.

Industry Engagement

Parker will showcase the CoolTherm portfolio, including TC850, at the Electric and Hybrid Vehicle Technology Expo in Stuttgart, where technical experts will discuss advancements in thermal management, structural adhesives, and related material solutions for next-generation battery systems.

This product introduction underscores the ongoing trend toward integrated thermal and structural management in battery pack engineering, supporting the industry’s drive for safer, lighter, and more efficient electric vehicles.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS