Metal rupture discs offer robust relief

OsecoElfab has developed a family of pressure-relief systems for lithium ion battery applications for heavy-duty, offroad e-mobility applications, writes Nick Flaherty.

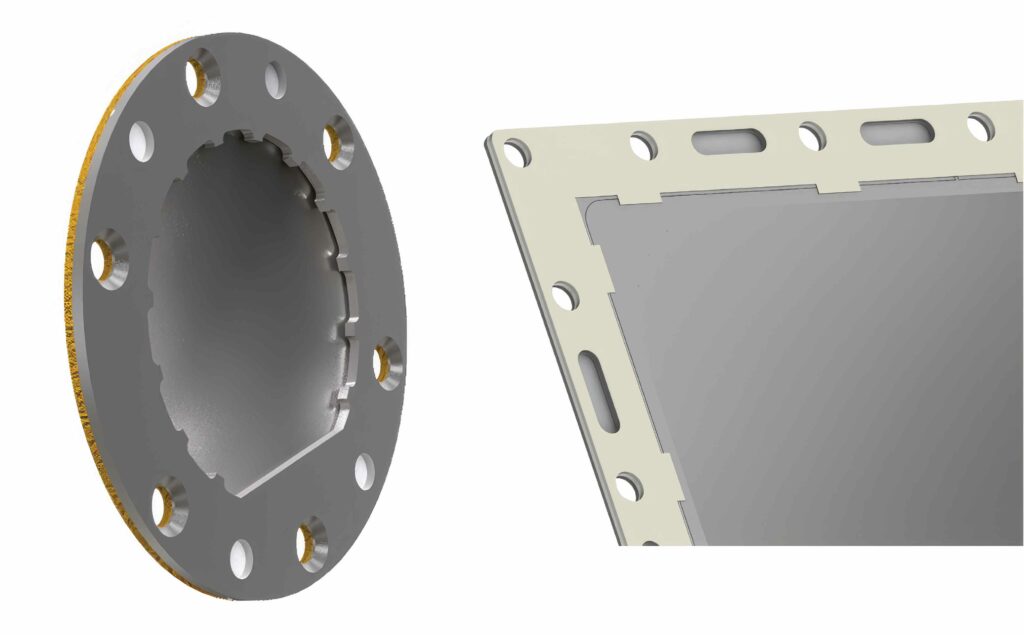

The low-profile, specialised, metal rupture discs support custom battery design to improve safety. They provide robust emergency relief and pressure equalisation in a single device in the event of outgassing by the battery cells.

The low burst pressure of 2 psi improves the ability to control and disperse flammable gases through a single vent, measuring 25.4 mm (1 in) to 304.8 mm (12 in), depending on the size of the pack.

Having a single rupture vent simplifies the assembly of the battery enclosure and enables a simpler, less expensive design.

There is an optional, breathable membrane that allows air and other gases to move in and out of the enclosure for ongoing pressure equalisation. This prevents a build-up of gases and pressure, and guards against any swelling or contracting of the enclosure.

The rupture discs provide fast, reliable and accurate emergency pressure relief where outgassing and pressure equalisation can be funnelled though a single device. Each disc can be supplied with different mounting arrangements to suit a specific battery or enclosure design via a bespoke service that considers the components, cells, packs and enclosures.

“We appreciate the unique design challenges presented by the need to conserve space while ensuring safety,” said Travis Nester, vice-president of sales and marketing.

“OE Lion actively supports this market with customisable solutions, designed to deliver accuracy and reliability with a minimal footprint.”

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS