24M ETOP battery technology boosts EV range by up to 50%

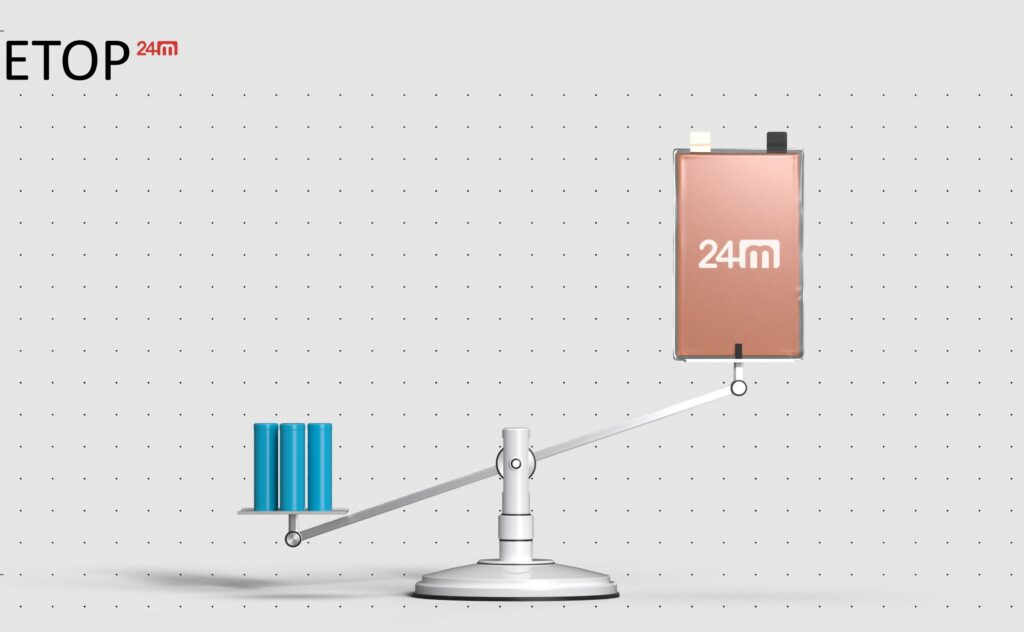

24M Technologies has unveiled its 24M ETOP (Electrode-to-Pack) battery pack technology, delivering up to 50% more electric vehicle range through unmatched energy density. This innovation replaces traditional lithium-ion battery construction by sealing electrodes in thin polymer films and integrating them directly into the battery pack, eliminating the need for individual cells and modules. Conventional battery packs typically contain a significant proportion of inactive materials such as metal casings and plastics, limiting energy density and adding cost. With 24M ETOP, electrodes can occupy up to 80% of the pack volume, compared to 30% to 60% in traditional designs, allowing manufacturers to pack far more energy into the same space or enable cost savings by using less expensive chemistries without sacrificing range.

For example, a 75kWh NMC battery common in mid-sized EVs can be increased to over 100kWh in the same footprint, boosting range by 33%. Alternatively, the technology allows switching to lower-cost lithium-iron phosphate chemistry while maintaining comparable range. Beyond density gains, ETOP enables unprecedented design freedom with battery packs customizable to virtually any size, shape or voltage, including oval or hexagonal shapes and configurations from 48V to 800V. Manufacturing is also simplified, as sealed electrodes require lower safety tolerances, improving yields while reducing capital expenditure on precision assembly equipment. The technology supports flexible series and parallel cell connections and allows cell formation to be performed in series, cutting formation equipment investment- the largest CAPEX item in current battery factories.

Naoki Ota, President and CEO of 24M Technologies, said, “Minimising packaging materials and wasted space, 24M ETOP brings a step change in performance, replacing traditional cell-to-module-to-pack construction with electrode-to-pack construction, maximising energy density. 24M ETOP makes it easier to build compact, flexible and safe high voltage batteries, presenting a revolutionary opportunity for electric vehicle manufacturers – longer ranges with the same chemistry or the same range with lower cost, safer chemistries, both in the same space. It truly is the closest version of an ideal battery – it is essentially all active material in a sophisticated wrapper.”

This breakthrough works seamlessly with 24M’s complementary technologies like the Impervio separator, Eternalyte electrolyte, and LiForever electrode, all aimed at creating safer, longer-lasting, and higher-performing batteries. Together, these innovations represent a fundamental reimagining of internal battery design and manufacturing, positioning 24M ETOP as a transformative solution for the future of electric mobility.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS