Advanced Clean Technology Expo 2025

(Image courtesy of Danfoss)

Getting in on the act

The 2025 Advanced Clean Transportation (ACT) Expo took place from April 28 to May 1, 2025 in Anaheim, California. Peter Donaldson reports on a selection of electrification products on the exhibition floor that piqued his interest

The ACT Expo is an annual opportunity for fleet operators involved in cargo and passenger transport – including long-distance, regional and local trucking and buses, and drayage – concerning ports, municipal services, utilities and refuse collection to meet industry and government to catch up with the technology that impacts their businesses.

oil-WEG heat exchangers

(Image courtesy of the author)

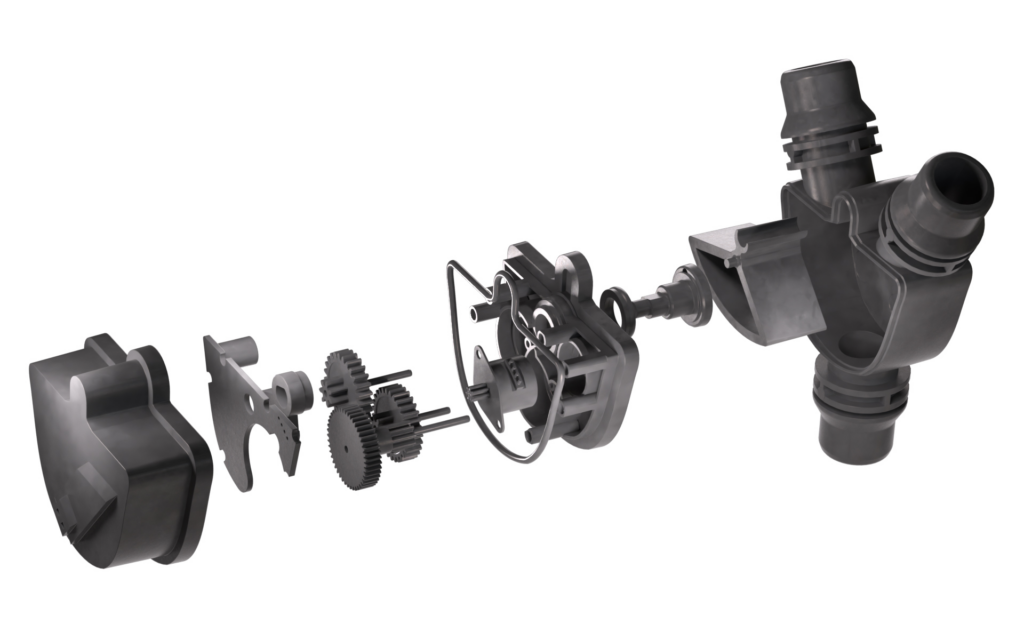

BorgWarner’s Cascadia Motion showcased its latest innovation in electric drive technology; the iM-575 integrated drive module. Designed for medium- to heavy-duty EVs, the iM-575 offers a highly efficient and compact propulsion solution tailored for OEMs and fleet operators seeking scalable electrification platforms, according to Jesus Molina of Cascadia Motion.

The iM-575 is a fully integrated unit comprising a BorgWarner HVH 320 series electric motor, a silicon carbide (SiC) inverter, and an advanced oil and water-ethylene glycol (WEG) dual-loop cooling system. The drive is capable of delivering 412 kW and 1048 Nm continuously, with respective peak power and torque figures of 652 kW and 1829 Nm. The unit can operate over a voltage range from 200 to 840 VDC, and has maximum speed of 7000 rpm. Three available stack lengths bring flexibility in configuration, and this modularity allows the iM-575 to be tailored to a variety of Class 6–8 commercial vehicle applications.

Central to the performance of the iM-575 is its thermally optimised architecture. The motor employs a fully flooded oil-cooled design, leveraging a mechanical G-rotor pump and an internal oil sump. This design ensures direct thermal contact with the rotor and stator, promoting uniform heat distribution and enhancing thermal efficiency. The WEG circuit is routed first through the inverter – the system’s thermally critical component – before passing through a cooling jacket that removes heat from the oil. Importantly, the oil and WEG circuits are thermally coupled but remain physically separate to prevent cross-contamination. The self-contained oil system and integrated oil–water heat exchangers reduce the system design and assembly burden for OEMs.

Compared with previous-generation units such as the iM-425, which utilised spray cooling, the immersion-cooled iM-575 offers a significant leap forward in terms of thermal management and efficiency. The combined system – motor and inverter – achieves up to 97% efficiency, aided by the SiC-based inverter that offers up to a 2% improvement over traditional silicon insulated-gate bipolar transistor counterparts.

“Our model, at Cascadia Motion, is to take fully developed serial-production-validated motors from BorgWarner, which are already launched in a serial application with a large volume car manufacturer or a commercial vehicle OEM, and then package them into fully integrated modules,” Molina says.

The iM-575 exemplifies this approach, offering OEMs and even individual conversion projects access to cutting-edge EV drivetrain technology with minimal barriers to integration.

Alpha units of the iM-575 are currently being delivered with machined billet housings ahead of full serial production. These early units allow OEMs to integrate and validate the system within their vehicle platforms prior to the release of production-tooled housings, scheduled for Q3 2025, with serial production ramping up by year-end.

Bosch unveiled its next-generation Fuel Cell Power Module (FCPM 300), a 300 kW hydrogen-based system tailored for commercial mobility applications. Peter Tadros of Bosch emphasises that the module represents a major step forward in power density and packaging efficiency, aligning with OEM demands for scalable, cost-effective zero-emission solutions in long-haul and high-utilisation vehicle segments.

The FCPM 300 integrates two horizontally stacked fuel cell assemblies within a compact envelope, complete with embedded electronics, compressors and fluid handling components. In this way, it combines the fuel cell stack and the subsystems for the hydrogen and air supplies, the cooling circuit and current supply in a single module.

The design marks a significant evolution from prior generations, emphasising modularity and compactness. “This was the principal advancement in this area; offering 300 kW, using two stacks and a more compact form factor that fits customer packaging in a much more efficient way.”

According to Tadros, a critical design challenge was maximising power output within a standardised form factor that serves a broad swath of heavy-duty use cases. The development team focused on achieving optimal balance between system size, power density and thermal management, ultimately targeting the 98% of applications where such parameters fall within operational expectations. For remaining edge cases – typically, high-load scenarios like sustained uphill transport – the solution lies in system-level balancing, such as supplemental energy storage, rather than over-designing the fuel cell module.

A key differentiator for Bosch is its global r&d and production footprint, which allows cross-regional learning and platform reuse. The FCPM 300 reflects design insights from first-generation deployments in Asia, Europe and North America, now tailored for heavy-duty Class 8 commercial vehicle demands. Full production is anticipated in 2028.

In parallel, Bosch continues development of hydrogen internal combustion engines (H2-ICE), featuring both port fuel injection and direct injection systems. While port injection offers a lower-cost entry point, direct injection achieves diesel-like efficiency and power density – critical for high-payload applications. Tadros highlights Bosch’s success in addressing injector durability in heavy-duty applications, a common challenge owing to the absence of lubricants typically present in gasoline. Through advanced materials selection and refined tolerances, the company has validated direct injection high-pressure injectors capable of withstanding millions of cycles with minimal wear.

From a strategic standpoint, Bosch maintains a technology-neutral approach, investing across battery-electric, hybrid, fuel cell and hydrogen ICE powertrains. Tadros emphasises that use case – especially factors such as payload, range and existing infrastructure – determines the appropriate solution. For long-range, light to medium operating power duty cycles, fuel cells offer efficiency advantages, while hydrogen ICEs are favoured for high-load, shorter-range scenarios owing to their robustness and cost alignment with existing diesel platforms.

With complementary innovations such as hydrogen electrolysers and cryogenic refuelling pumps from Bosch Rexroth, Bosch is positioning itself to provide full-spectrum hydrogen mobility solutions, focused on reducing the total cost of ownership (TCO) across the commercial transport sector.

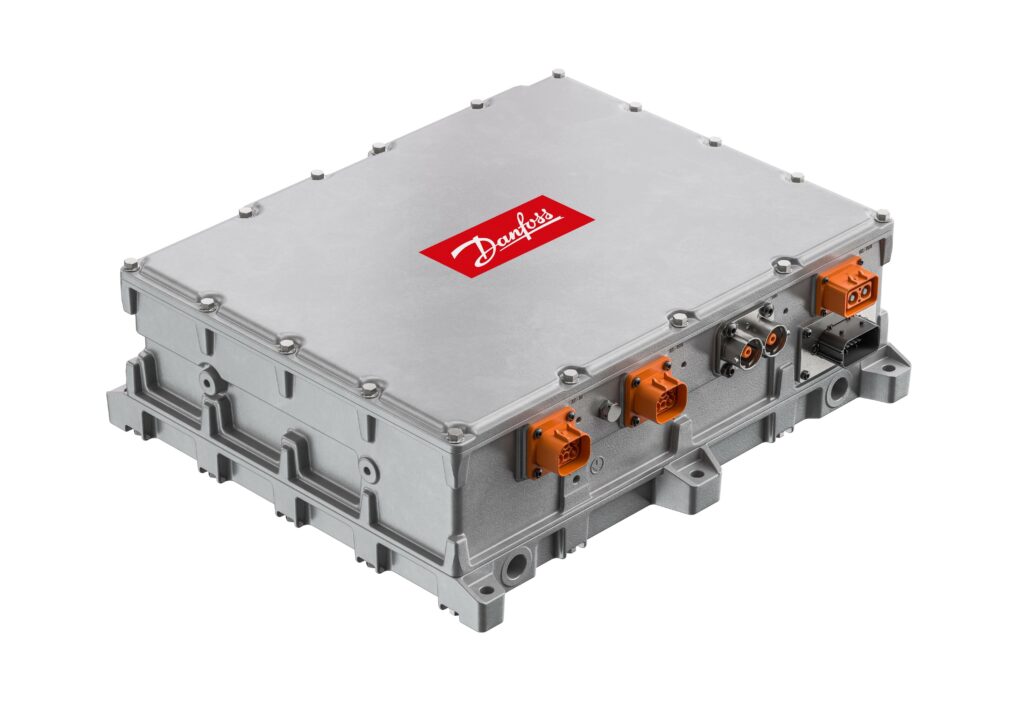

Danfoss highlighted three integrated electrification solutions tailored for both on- and off-highway applications at the show: the ED3 onboard charger with electric power take-off (EPTO), an e-hydraulic power module, and the newly introduced e-power pack. Together, these systems address the growing demand for modular, scalable electrification components that streamline vehicle integration and reduce the TCO.

The ED3 unit consolidates high-power onboard charging and EPTO capabilities into a single package, says Danfoss’ Cameron Guernsey. Designed primarily for medium- and heavy-duty trucks, the ED3 supports AC charging up to 44 kW – double the rate of conventional 20 kW solutions – significantly reducing charging time. Additionally, it provides both AC and DC EPTO outputs, enabling efficient operation of auxiliary systems such as transport refrigeration units.

Crucially, the ED3 includes galvanic isolation for all EPTO outputs, protecting high-voltage battery systems from external faults. This allows OEMs to provide power access points for builders of truck bodies or trailer systems without compromising battery safety. “The ED3 is gaining traction in emerging e-trailer configurations, where it enables the use of battery-powered refrigeration systems or regenerative e-axles,” Guernsey notes.

For OEMs looking to electrify hydraulic work functions while minimising system complexity, Danfoss offers a dedicated e-hydraulic power module. “This solution combines a low-speed, high-torque electric motor with a hydraulic pump and inverter in a compact assembly. It allows body builders to maintain familiar hydraulic interfaces while offloading electrification complexity to OEMs and suppliers,” he adds.

The system supports standard hydraulic pump form factors – thanks to a female motor shaft interface – while optional Danfoss hydraulic pumps enable turnkey integration. Advanced control algorithms are in development to optimise motor efficiency, particularly at low pump speeds (e.g. ~2200 rpm), which is where hydraulic systems typically operate. This fine-tuned control ensures responsive performance and energy efficiency – key factors in achieving TCO targets.

The e-power pack is a fully integrated low-voltage (12–48 V) motor-inverter assembly, optionally equipped with a small hydraulic pump. Developed for applications such as scissor lifts, boom lifts, and auxiliary systems on utility trucks, it addresses markets where lower power requirements and safety considerations make high-voltage solutions impractical.

Its small footprint and plug-and-play architecture make it ideal for early stage electrification deployments, acting as ‘gateway technology’ for OEMs transitioning to electric systems, Guernsey explains. Its low infrastructure burden – requiring only basic grid access for charging – further enhances its appeal in indoor or low-duty applications.

With these three modular systems, Danfoss provides a flexible electrification toolkit that supports vehicle manufacturers across a spectrum of applications from high-voltage propulsion support to low-voltage actuation and auxiliary power.

Electrovaya attended the ACT Expo in search of “new verticals,” according to the company’s Dr. Jeremy Dang, having established its high-temperature-safe and long-life expectancy lithium-ion battery technology in material handling and automated guided vehicles. “We are looking for other applications such as buses, military vehicles and energy storage where we can leverage the benefits of our cell properties.”

At the core of Electrovaya’s safety proposition is a proprietary and patented ceramic-based separator integrated within their nickel-manganese-cobalt cells. While standard industry practice for consumer electronics employs basic polymer separators, which can shrink and melt at temperatures typically above 100 C leading to thermal runaway, more sophisticated suppliers apply a ceramic coating to these polymer separators to enhance thermal stability. “Electrovaya takes this a critical step further by embedding a fully ceramic membrane. This innovative design allows their cells to maintain stability beyond 250 C, significantly mitigating the risk of thermal events,” Dang says.

The paramount benefit of this elevated thermal stability is the prevention of internal short circuits. In high-current, heavy-duty applications, cells naturally generate heat owing to internal resistance. A compromised separator, caused by excessive temperature, can lead to direct contact between the anode and cathode, resulting in a short circuit and potential ignition of volatile electrolytes. By maintaining separator integrity at substantially higher temperatures, Electrovaya’s technology prevents these critical failure modes, enhancing operational safety and reliability. The company reports no thermal events across over 30,000 units deployed in the field over more than a decade.

Beyond safety, the ceramic separator unexpectedly confers a significant longevity advantage. While the precise mechanisms remain proprietary, third-party testing has verified that Electrovaya’s batteries can achieve up to 14,000 charge cycles; a remarkable improvement over the industry standard of 3000–4000 cycles for typical lithium batteries. This translates to a potential lifespan of 20 years or more in high-utilisation environments such as 24/7 distribution centres, drastically reducing the TCO and environmental impact through less-frequent battery replacement.

Electrovaya’s in-house developed Battery Management System (BMS) further augments safety and performance. The BMS continuously monitors cell voltage and temperature every 10 s, ensuring operation within defined safe limits (e.g., −30 to +50 C operating range). The system incorporates robust redundancy in sensing and intelligent filtering of outlier data, preventing operation under hazardous conditions and safeguarding the battery from overvoltage, undervoltage and excessive current draws that could damage contactors or fuses. This represents an integrated approach, combining advanced material science at the cell level with intelligent electronic management.

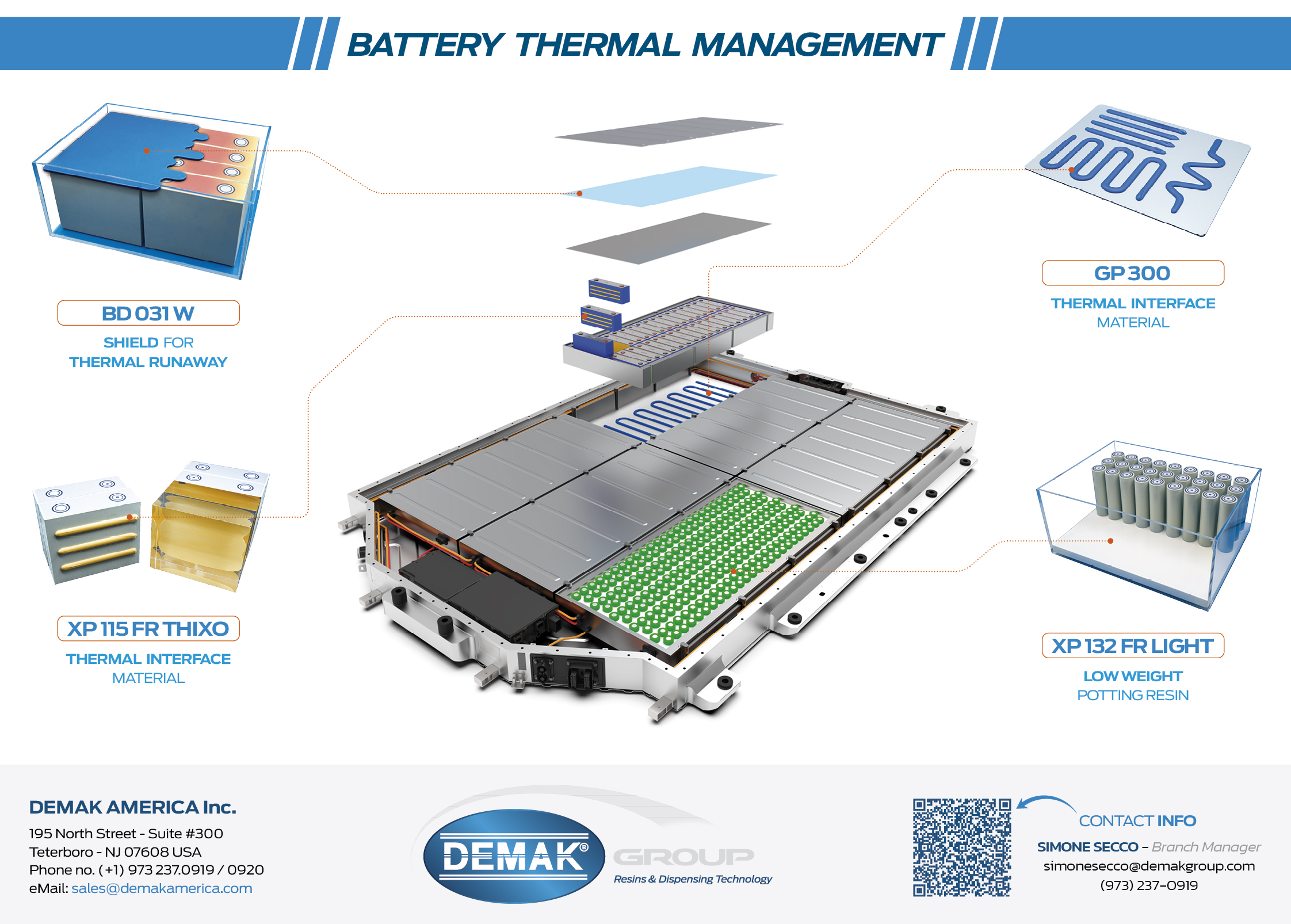

EQYO, a subsidiary of the Saint–Gobain Group with extensive expertise in seals and bearings, has introduced a novel component for thermal management systems: the ‘Triangle Valve.’ This three-way, two-position proportional valve prioritises optimal sealing performance, according to EQYO’s Christian Elz. Developed through an internal “hackathon,” the Triangle Valve aims to unlock significant efficiency gains in fluid control within EV thermal management loops.

Traditional valve designs often treat seals and bearings as late-stage considerations, leading to compromises in efficiency, Elz points out. EQYO’s Triangle Valve, conversely, started with the ideal seal design and its optimal placement. The core innovation lies in its moving body, shaped like a triangle with its longest side curved, which allows for the replacement of multiple dynamic seals with a single, centrally located dynamic seal. In a conventional three-port ball valve, each port requires a seal against the rotating inner body, resulting in at least three active seals with a distance to the centre of rotation, constantly generating friction. The Triangle Valve, however, positions its single dynamic seal directly at the centre of rotation, dramatically reducing frictional torque.

“This innovative sealing approach translates directly into substantial efficiency improvements. Comparative testing against aftermarket benchmarks has demonstrated that the Triangle Valve can be approximately 60 percent more efficient in terms of mechanical movement. Furthermore, in hydraulic properties, it exhibits up to a 45 percent lower pressure drop,” Elz says.

The valve itself is a three-port, two-position controllable and proportional unit. The triangular element within the valve pivots to control fluid flow, allowing for precise proportional distribution between the two output ports. For example, if positioned centrally, it can achieve a 50:50 flow split; if adjusted, it can proportionally divide the flow (e.g. 70:30). This proportionality enables fine-tuned thermal management, allowing precise control over coolant distribution to various EV components such as battery packs, power electronics and electric motors.

Beyond efficiency, the Triangle Valve offers benefits in terms of complexity and potential service life. By halving the number of solid plastic parts and reducing the number of dynamic seals from three to one compared with conventional designs, the valve inherently reduces component count and potential points of failure. EQYO anticipates similar or improved durability compared with existing benchmarks, supported by rigorous in-house testing on dedicated test rigs.

EQYO is currently manufacturing B-samples of the Triangle Valve and is actively seeking partners for the next development phase (C-sample) to customise the mechanical section and/or drive unit for specific customer requirements.

Kempower presented its Megawatt Charging System (MCS), which it is developing for heavy-duty truck and bus applications. Established in 2017, the Finnish DC fast-charging manufacturer provides distributed and dynamic charging systems for both charge-point operator and fleet segments, with its presence at the ACT Expo emphasising its fleet-focused offerings.

Slated for release by the end of the year, the MCS is designed to meet the high power demands of truck charging, delivering a substantial 1.2 MW. This is achieved by linking two separate 600 kW power cabinets, says Jed Routh of Kempower. The MCS features its dedicated ‘megawatt charging satellite’ dispenser, equipped with a heavy-duty 700 A cable capable of handling the immense power transfer. While existing chargers can be adapted, their cable limitations would restrict full megawatt capability.

“Developing such a high-power system presents unique engineering challenges. Thermal management is critical; while the main power cabinets remain air-cooled, the megawatt charging satellite itself employs liquid cooling to dissipate the significant heat generated,” Routh explains. Cable management is another key consideration, necessitating designs that ensure ease of use and safety for drivers, Routh continues. Kempower’s MCS dispenser incorporates lifting assistance to aid in handling the substantial cable.

A primary hurdle in MCS deployment is the evolving industry standard, particularly concerning software communication protocols for the charger-to-truck handshake. Kempower is developing an MCS ahead of a fully solidified standard, an approach that introduces the risk of mid-stream changes requiring re-engineering efforts. Despite these challenges, Kempower is actively engaged in pilot projects, with early deployments already in Europe and planned for late Q4 2025 in the US, focusing on non-public test sites. These initial deployments will feature the MCS plug, with a high-power CCS plug variant planned for a subsequent generation.

The MCS is based on Kempower’s modular power unit architecture. This architecture scales from 50 to 600 kW across one to three power cabinets. This power can be dynamically distributed to up to eight individual dispensers, termed ‘satellites.’ While the standard satellites cater to public charging with integrated screens and payment options, the company is introducing a ‘control unit’ dispenser for fleet applications. This wall- or ceiling-mountable box, recently UL certified for North America, eliminates public-facing features such as payment terminals, thereby streamlining the charging process for fleet operators.

Kempower anticipates that megawatt charging will primarily serve heavy-duty vehicles, given the significant infrastructure investment required, including grid connections and potential microgrid solutions. Acknowledging that the goal of a “five or 10 minute charge” for passenger cars is being explored by some, Routh expresses reservations about its societal cost-benefit given existing fast-charging capabilities. Thus, Kempower’s focus remains on providing robust, scalable charging solutions essential for the accelerating electrification of commercial vehicle fleets.

Parker Hannifin’s Motion Systems Group presented a multi-speed transmission specifically engineered for e-motors in heavy-duty trucks and similar vehicles. Developed in a strategic alliance with an undisclosed partner, this transmission is designed to offer a compelling alternative to e-axle solutions, emphasising flexibility, scalability and cost-effectiveness for a wide range of Class 2 through Class 8 applications, says Parker’s Jay Schultz.

A key design feature is the transmission’s direct mounting capability to their Global Back-Mount electric motors, eliminating the need for bell housings or other complex adapters. The transmission is designed to accommodate the high-speed input characteristics of modern e-motors. Unlike traditional diesel engines that operate at a maximum of around 3500-4000 rpm, e-motors can efficiently spin at much higher speeds, with Parker’s motors designed to reach inputs of up to 9000 rpm. “This leverages the ‘free power’ of high-RPM e-motors, where increased speed translates directly to increased power without a significant cost penalty, while the transmission ensures the necessary torque delivery,” Schultz explains.

The multi-speed design is critical for managing the power-torque trade-off inherent in electric motors. At high rpm, while power is abundant, torque can be limited. The transmission’s multiple ratios address this by providing high torque in lower gears (e.g., first gear ratios from 2:1 to 6.6:1 for heavy-duty models) for launch and acceleration, and then switching to higher gears (e.g., second gear ratios from 0.85:1 to 2.16:1 for heavy-duty models) for efficient high-speed cruising. This allows vehicles to achieve both strong low-end performance and desired top speeds. The heavy-duty two-speed transmission is paired with Parker’s 310 series motor, while a lighter-duty two-speed version (first gear max 4.3:1, second gear max 2.5:1) is optimised for their 210 series motor.

Parker’s radial flux, internal permanent magnet (IPM) AC motors are notable for their unique design that eschews reluctance torque, a common characteristic in many competitor IPM motors. This design choice, while potentially yielding slightly lower peak efficiency at a single operating point, results in a significantly flatter efficiency plateau across a much wider operating range (e.g., 2000 to 7500 rpm). For real-world drive cycles involving frequent stopping and starting, this translates to superior overall energy conversion from battery to shaft power, with internal testing suggesting up to 20% greater efficiency compared with reluctance-hybrid IPM designs over a duty cycle, Shultz notes.

Beyond performance, the multi-speed transmission enhances safety and redundancy in EV powertrains. By providing multiple ratios, it helps manage back electromotive force voltage, preventing it from exceeding bus voltage limits, especially crucial in older 400 V systems. The ability to shift into a neutral state also offers a critical safety mechanism, decoupling the motor from the wheels in case of inverter malfunction, thereby effectively reducing the back voltage to zero and protecting downstream electronics.

Proterra presented the H2-23, a new variant within their Onyx Strata platform, specifically engineered for Class 8 applications. This 125 kWh pack represents Proterra’s highest energy density offering to date, pushing beyond 175 Wh/kg. Designed and manufactured in the United States, the H2-23 is based on cylindrical format cells, with Proterra managing the complete pack assembly from cell integration upwards, according to Proterra’s Claire McConnell and Mabel Feng.

Cylindrical cells represent a strategic choice for Proterra’s entire Onyx platform. This commodity form factor offers a broad supplier base and continuous innovation, also allowing Proterra to achieve a balanced approach to pack size, energy capacity and voltage. For the H2-23, a new module variant was designed to meet the packaging requirements of heavy-duty trucks. “While energy density is prioritised for large trucks owing to weight considerations, Proterra is actively exploring increased power delivery to prevent the battery from becoming a bottleneck as charging infrastructure advances,” McConnell says.

The H2-23, like other Onyx packs, features a robust enclosure design that eschews traditional clamshells or plastic, opting instead for sturdy extrusions or die-cast materials. This rugged approach means that the pack is designed to withstand impacts as if there were no surrounding chassis protection. Internally, a structural cooling plate doubles as a cross-member, providing additional structural protection along the length of the pack.

Within the modules, Proterra implements a multi-layered approach to passive propagation resistance, aiming to prevent thermal runaway spread from a single cell failure. Unlike designs with large arrays of cells, Proterra incorporates physical barriers and insulator protection layers between modules. A unique feature is the dedicated vent for each of the 23 modules within the H2-23 pack. “This design focuses on slowing down and spreading out the energy impulse over time, preventing rapid, high-energy thermal events. Proterra’s packs are tested to ensure that a single cell failure does not propagate throughout the entire pack,” Feng explains.

The Battery Management System (BMS) is integral to the H2-23’s performance and safety. While working with a third-party for core BMS hardware, Proterra retains extensive control over the application layer, including charge control, algorithms and thermal settings. Each pack contains a main BMS, and each module features a localised monitoring board that feeds data back to the main BMS. In multi-pack Class 8 truck configurations, the BMS units communicate, rotating a ‘leader’ role to ensure that all packs are balanced and degrade uniformly. This architecture allows for temporary string or pack disconnection in case of a fault, enabling the vehicle to continue operation and avoid being stranded. McConnell and Feng report strong interest in the H2-23.

Click here to read the latest issue of E-Mobility Engineering.

ONLINE PARTNERS